Your Ultimate Guide to Sourcing Vending Machine Dolly

Guide to Vending Machine Dolly

- Introduction: Navigating the Global Market for vending machine dolly

- Understanding vending machine dolly Types and Variations

- Key Industrial Applications of vending machine dolly

- Strategic Material Selection Guide for vending machine dolly

- In-depth Look: Manufacturing Processes and Quality Assurance for vending machine dolly

- Comprehensive Cost and Pricing Analysis for vending machine dolly Sourcing

- Spotlight on Potential vending machine dolly Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for vending machine dolly

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine dolly Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vending machine dolly

- Strategic Sourcing Conclusion and Outlook for vending machine dolly

Introduction: Navigating the Global Market for vending machine dolly

In today’s dynamic global marketplace, the importance of efficient logistics cannot be overstated, particularly in industries reliant on vending machines. A vending machine dolly serves as a critical tool in this ecosystem, facilitating the transport of vending machines with ease and safety. For international B2B buyers, especially those based in Africa, South America, the Middle East, and Europe, understanding the nuances of this essential equipment can significantly impact operational efficiency and cost-effectiveness.

This comprehensive guide delves into various aspects of vending machine dollies, including their types, materials, and manufacturing processes. It offers insights into quality control measures that ensure durability and performance, which are vital for maintaining a competitive edge in your market. Additionally, we highlight reputable suppliers with a track record of delivering high-quality products tailored to diverse regional needs.

As you navigate through this guide, you will find detailed analyses of cost factors, market trends, and frequently asked questions that can empower your sourcing decisions. Whether you are in Colombia seeking innovative solutions or in Italy looking to optimize your supply chain, this resource equips you with the knowledge to make informed, strategic purchasing decisions. By leveraging these insights, you can enhance operational workflows, reduce downtime, and ultimately drive profitability in your vending machine operations.

Understanding vending machine dolly Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Vending Dolly | Flat platform with two wheels for easy maneuvering | General vending machine transport | Pros: Cost-effective, lightweight. Cons: Limited load capacity. |

| Heavy-Duty Vending Dolly | Reinforced frame and larger wheels | Large vending machines, bulk items | Pros: High load capacity, durable. Cons: More expensive, heavier. |

| Folding Vending Dolly | Collapsible design for easy storage | Small businesses, event setups | Pros: Space-saving, portable. Cons: Less stability with heavy loads. |

| Electric Vending Dolly | Battery-operated for automated lifting | High-volume vending operations | Pros: Reduces physical strain, efficient. Cons: Higher maintenance costs. |

| Specialty Vending Dolly | Designed for specific machine types (e.g., snack, beverage) | Niche markets, specific vending needs | Pros: Tailored design, optimal fit. Cons: Limited versatility across machine types. |

Standard Vending Dolly

The standard vending dolly is a flat platform with two wheels, designed for easy maneuverability in tight spaces. This type is ideal for general vending machine transport, making it suitable for businesses that frequently relocate machines or restock supplies. When considering a purchase, buyers should evaluate the load capacity and material quality, as these factors can influence longevity and performance. This dolly is typically cost-effective, but its limited load capacity may not suit all applications.

Heavy-Duty Vending Dolly

Heavy-duty vending dollies feature a reinforced frame and larger wheels, allowing them to handle more substantial loads. They are essential for transporting larger vending machines and bulk items, making them suitable for businesses that require frequent heavy lifting. Buyers should assess the weight limits and durability features when selecting a heavy-duty dolly. While these dollies offer high load capacities and durability, they tend to come at a higher price point and can be cumbersome to maneuver.

Folding Vending Dolly

Folding vending dollies are designed to collapse for easy storage, making them an excellent choice for small businesses or event setups where space is limited. Their portability allows for convenient transport between locations. However, buyers should be cautious about their stability, particularly when handling heavier loads. The space-saving feature is a significant advantage, but the reduced stability may limit their effectiveness in certain high-capacity scenarios.

Electric Vending Dolly

Electric vending dollies are equipped with a battery-operated lifting mechanism, significantly reducing the physical strain on operators during heavy lifting tasks. These dollies are particularly advantageous for high-volume vending operations where efficiency is critical. When considering an electric dolly, buyers should factor in battery life and maintenance costs. Although they enhance productivity and ease of use, the initial investment and ongoing maintenance can be higher than manual options.

Specialty Vending Dolly

Specialty vending dollies are designed for specific types of vending machines, such as snack or beverage dispensers. Their tailored design ensures an optimal fit, making them suitable for niche markets and specialized vending needs. Buyers should carefully consider the type of vending machines they operate before selecting this dolly type, as versatility can be limited. While they provide an excellent solution for specific applications, their lack of adaptability may not justify the investment for businesses with varied machine types.

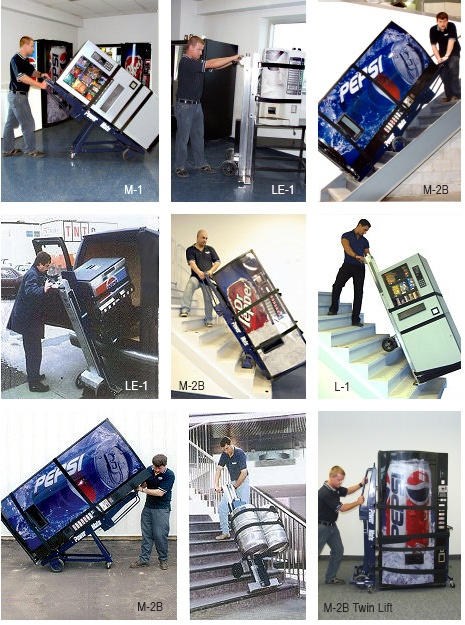

Related Video: How to Move a Vending Machine or Safe in 30 Seconds | Safe & Appliance Dolly – 1600 lbs Capacity

Key Industrial Applications of vending machine dolly

| Industry/Sector | Specific Application of vending machine dolly | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Transporting vending machines to various locations | Increases efficiency in setup and relocation of machines | Load capacity, maneuverability, and durability of materials |

| Hospitality | Moving machines for events and catering services | Facilitates quick service changes and enhances customer experience | Stability during transport, ease of use, and compact design |

| Office Environments | Delivering snacks and beverages to different floors | Streamlines refreshment services and boosts employee morale | Size compatibility with elevators, weight limits, and ergonomic design |

| Educational Institutions | Setting up vending machines in schools and universities | Supports student needs with easy access to refreshments | Compliance with safety standards, ease of transport in tight spaces |

| Healthcare | Relocating vending machines in hospitals and clinics | Ensures timely access to food and drinks for patients and staff | Hygiene standards, mobility in crowded areas, and stability during use |

Retail

In the retail sector, vending machine dollies are essential for transporting machines to various locations within stores or shopping centers. They solve logistical challenges by enabling quick and efficient setup and relocation, which is crucial during promotions or seasonal changes. Buyers in this sector should consider the load capacity and maneuverability of the dolly, especially in crowded environments. Durable materials are also important to withstand the rigors of frequent use.

Hospitality

In the hospitality industry, vending machine dollies are invaluable for moving machines to different venues during events or catering services. This application enhances operational efficiency by allowing staff to quickly set up or relocate machines, thereby improving customer satisfaction. Buyers should prioritize stability during transport and ease of use, as well as a compact design to navigate tight spaces. Compliance with service standards is also crucial to ensure a seamless experience.

Office Environments

In office environments, vending machine dollies are used to deliver snacks and beverages to various floors, enhancing workplace convenience. This application streamlines refreshment services, ultimately boosting employee morale and productivity. Buyers need to consider the size of the dolly to ensure it fits in elevators and hallways, as well as weight limits that ensure safe transport. Ergonomic design features can also enhance usability for staff.

Educational Institutions

In schools and universities, vending machine dollies facilitate the setup of machines that cater to student needs. They enable efficient access to refreshments during busy hours, supporting both learning and social interactions. Buyers in this sector should focus on compliance with safety standards to ensure the safety of students and staff. The dolly’s ability to navigate tight spaces is also essential, as many educational facilities have limited room for movement.

Healthcare

In healthcare settings, vending machine dollies are crucial for relocating machines within hospitals and clinics. They ensure timely access to food and drinks for patients and staff, contributing to overall well-being. Buyers should pay attention to hygiene standards, as the dolly must be easy to clean and maintain. Additionally, the ability to maneuver in crowded areas and provide stability during use is critical for effective operation in these environments.

Related Video: DIY Vending Machine – Arduino based Mechatronics Project

Strategic Material Selection Guide for vending machine dolly

When selecting materials for vending machine dollies, international B2B buyers must consider various factors that influence performance, durability, and cost-effectiveness. Below is an analysis of four common materials used in the manufacturing of vending machine dollies, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Aluminum

Key Properties: Aluminum is lightweight yet strong, with excellent corrosion resistance. It can withstand moderate temperatures and is suitable for various environments.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which enhances maneuverability and ease of handling. It is also resistant to rust, making it ideal for humid or wet conditions. However, aluminum can be more expensive than steel, and its strength may not match that of heavier materials under extreme loads.

Impact on Application: Aluminum is compatible with a variety of media, including food products and beverages, making it a suitable choice for vending machine applications.

Specific Considerations: In regions like Europe, compliance with standards such as DIN can affect material selection. Buyers should also consider the availability of aluminum recycling facilities, which may influence sustainability practices.

Steel (Carbon Steel)

Key Properties: Carbon steel is known for its high tensile strength and durability. It can handle high pressure and temperature ratings, making it suitable for heavy-duty applications.

Pros & Cons: Steel is cost-effective and offers excellent strength, making it ideal for heavy loads. However, it is prone to corrosion if not properly coated or treated, which can be a significant drawback in humid environments.

Impact on Application: Carbon steel is suitable for transporting heavy vending machines, but its susceptibility to rust means that it may not be ideal for applications involving moisture or corrosive substances.

Specific Considerations: Buyers from Africa and South America should be aware of local standards for steel quality and corrosion resistance. Compliance with ASTM standards may be necessary for international trade.

Stainless Steel

Key Properties: Stainless steel is highly resistant to corrosion and staining, with good strength and temperature resistance. It is often used in environments where hygiene is a priority.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust, making it ideal for various climates. However, it is more expensive than carbon steel and can be heavier, which may affect maneuverability.

Impact on Application: Stainless steel is particularly suitable for vending machines that dispense food or beverages, as it maintains hygiene standards and is easy to clean.

Specific Considerations: In regions like the Middle East, where high temperatures and humidity can affect material performance, stainless steel’s properties may offer significant advantages. Compliance with local health and safety regulations is also essential.

Polypropylene

Key Properties: Polypropylene is a thermoplastic polymer known for its chemical resistance and lightweight nature. It can withstand moderate temperatures and is often used in various consumer products.

Pros & Cons: The key advantage of polypropylene is its resistance to a wide range of chemicals, making it suitable for transporting various products. It is also lightweight and cost-effective. However, it may not provide the same level of strength as metals, limiting its use in heavy-duty applications.

Impact on Application: Polypropylene is suitable for lighter vending machine applications, especially those involving non-food items or products that require chemical resistance.

Specific Considerations: Buyers in South America and Africa should consider local availability and recycling options for polypropylene, as well as compliance with regional material standards.

Summary Table

| Material | Typical Use Case for vending machine dolly | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | General service, lightweight vending machines | Lightweight, corrosion-resistant | Higher cost, lower strength | Medium |

| Steel (Carbon Steel) | Heavy-duty applications for vending machines | Cost-effective, high strength | Susceptible to corrosion | Low |

| Stainless Steel | Food and beverage vending machines | Durable, corrosion-resistant | Higher cost, heavier weight | High |

| Polypropylene | Lighter applications, non-food items | Chemical resistance, lightweight | Limited strength | Low |

This guide offers a comprehensive overview of material selection for vending machine dollies, enabling international B2B buyers to make informed decisions tailored to their specific market conditions and operational needs.

In-depth Look: Manufacturing Processes and Quality Assurance for vending machine dolly

Manufacturing Processes for Vending Machine Dolly

Understanding the manufacturing processes of a vending machine dolly is crucial for B2B buyers, particularly those sourcing from diverse regions such as Africa, South America, the Middle East, and Europe. The production of a vending machine dolly typically involves several key stages: material preparation, forming, assembly, and finishing.

Material Preparation

The first step in manufacturing a vending machine dolly involves selecting high-quality materials. Common materials include aluminum, steel, and high-density plastics. B2B buyers should ensure that suppliers use materials that are not only durable but also lightweight to facilitate ease of handling and transportation.

Once the materials are chosen, they undergo treatment processes, such as cutting and welding, to prepare them for the next manufacturing stages. Buyers should inquire about the suppliers’ sourcing practices to ensure compliance with international standards and sustainability practices.

Forming

The forming stage focuses on shaping the dolly components. Techniques such as stamping, bending, and extrusion are commonly used.

- Stamping: This method involves using a die to cut and shape metal sheets into specific forms. It is efficient for producing large quantities of uniform parts.

- Bending: This technique alters the shape of the metal components to form the dolly’s frame.

- Extrusion: Often used for plastic components, extrusion allows for the creation of complex shapes that can enhance the dolly’s functionality.

B2B buyers should evaluate the forming techniques employed by suppliers to ensure they meet the required specifications and performance standards.

Assembly

The assembly process is where all the formed components come together. This stage typically includes:

- Joining techniques: Such as welding, riveting, or using fasteners to ensure that all parts are securely affixed.

- Integration of additional features: Such as wheels, handles, and safety mechanisms which enhance usability.

During assembly, it is essential for manufacturers to maintain strict adherence to design specifications. Buyers should request details about assembly line processes and the qualifications of assembly personnel to guarantee quality workmanship.

Finishing

The final stage in the manufacturing process is finishing. This typically involves:

- Surface treatment: Processes like powder coating, painting, or galvanizing to enhance aesthetics and protect against corrosion.

- Quality checks: Ensuring all products meet the desired finish and are free from defects.

Buyers should ensure that their suppliers have robust finishing capabilities and that the final product aligns with their branding and quality expectations.

Quality Assurance in Manufacturing

Quality assurance (QA) is integral to the manufacturing of vending machine dollies, ensuring that products are safe, reliable, and compliant with international standards.

International Standards

B2B buyers should be familiar with relevant international quality standards, including:

- ISO 9001: This standard outlines criteria for a quality management system and is crucial for ensuring consistent quality in manufacturing processes.

- CE Marking: This certification indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

For buyers in Africa and South America, it is also important to consider local certifications that may be required for import compliance.

Quality Control Checkpoints

Quality control (QC) involves several critical checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This stage checks the quality of raw materials before they are used in production. Buyers should ask suppliers how they assess material quality upon arrival.

- In-Process Quality Control (IPQC): This ensures that quality checks are conducted at various stages during manufacturing, allowing for the detection of defects early in the process.

- Final Quality Control (FQC): At this stage, the finished product is thoroughly inspected and tested to ensure it meets all specifications before shipping.

B2B buyers should request documentation of these QC processes from suppliers to verify compliance.

Common Testing Methods

Testing methods used to validate the quality of vending machine dollies include:

- Load testing: Evaluating the dolly’s capacity to carry weight without failure.

- Durability testing: Assessing the resistance of the dolly to wear and tear over time.

- Safety testing: Ensuring that all safety features function correctly.

Buyers should inquire about the testing protocols and equipment used by suppliers, as well as the frequency of testing to ensure consistency.

Verifying Supplier Quality Control

To ensure that suppliers maintain high standards of quality, B2B buyers can take several actionable steps:

- Conduct Audits: Regular audits of manufacturing facilities can provide insights into the supplier’s adherence to quality standards. This can be done through either in-person visits or remote audits.

- Review Quality Reports: Request detailed quality assurance reports from suppliers, documenting their QC processes, testing results, and any corrective actions taken.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of product quality and compliance with specifications.

Navigating QC Nuances for International Buyers

International buyers must be aware of the nuances in quality control across different regions. For instance, regulations and standards can vary significantly between Europe and Africa or South America. Buyers should:

- Stay Informed on Local Compliance: Understand the specific quality standards and regulations that apply in their target markets.

- Assess Supplier Certifications: Verify that suppliers hold the necessary certifications for both their local region and the buyer’s market.

By focusing on these aspects, B2B buyers can better navigate the complexities of manufacturing processes and quality assurance, ensuring they select suppliers capable of meeting their requirements for vending machine dollies.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for vending machine dolly Sourcing

Understanding the Cost Structure of Vending Machine Dollies

When sourcing vending machine dollies, international B2B buyers should familiarize themselves with the cost components that contribute to the overall pricing. The primary elements include:

-

Materials: The choice of materials directly impacts costs. Common materials for dollies include aluminum, steel, and plastic, each with its own pricing and weight implications. Consider sourcing from suppliers that offer sustainable materials, as this can also appeal to environmentally conscious markets.

-

Labor: Labor costs vary significantly across regions. In South America and Africa, lower labor costs might offset higher material expenses, while in Europe, labor costs are generally higher. Understanding local labor markets can lead to better negotiations.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and indirect labor. Buyers should inquire about the manufacturing location, as overhead can vary widely based on regional economic conditions.

-

Tooling: Custom tool creation for specific dolly designs can add to initial costs. However, investing in quality tooling can lead to better product consistency and durability.

-

Quality Control (QC): Implementing robust QC processes ensures the dolly meets specified standards, thereby preventing costly returns or replacements. Buyers should assess the supplier’s QC protocols to avoid future issues.

-

Logistics: Shipping costs can fluctuate based on distance, weight, and shipping method. For international buyers, understanding Incoterms (International Commercial Terms) is crucial, as these dictate responsibilities for shipping, insurance, and tariffs.

-

Margin: Suppliers will typically add a margin to their costs. Understanding the standard margins in different regions can help buyers gauge whether they are getting a fair deal.

Influencers on Pricing

Several factors can significantly influence the pricing of vending machine dollies:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchasing often results in lower per-unit costs. Buyers should negotiate MOQs to maximize cost savings, especially when entering new markets.

-

Specifications/Customization: Custom features can increase costs. Buyers should balance the need for customization with budget constraints and market demand.

-

Materials: Higher-quality materials can lead to increased durability and longer lifespans, justifying higher upfront costs. However, buyers should ensure the benefits align with their operational needs.

-

Quality/Certifications: Products that meet specific industry certifications (e.g., ISO, CE) may command higher prices but can also enhance credibility and marketability.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can affect pricing. Conducting due diligence on potential suppliers is essential for ensuring quality and service.

-

Incoterms: The choice of Incoterms can impact the total landed cost. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers negotiate better shipping arrangements.

Buyer Tips for Effective Sourcing

-

Negotiate Wisely: Leverage market knowledge and competitor pricing to negotiate better deals. Establishing long-term relationships with suppliers can also lead to advantageous pricing.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price, but the overall cost associated with ownership, including maintenance, durability, and potential resale value.

-

Understand Pricing Nuances: Be aware that pricing can fluctuate based on geopolitical factors, currency exchange rates, and trade policies, especially relevant for buyers from Africa and the Middle East.

-

Leverage Local Insights: Buyers from regions like Colombia and Italy should tap into local market knowledge and networks to find reputable suppliers and negotiate effectively.

-

Request Transparent Quotations: Ask suppliers for detailed breakdowns of costs to understand where savings can be made and to ensure transparency in pricing.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough market research and supplier assessments before finalizing any agreements.

Spotlight on Potential vending machine dolly Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for vending machine dolly.)*

Essential Technical Properties and Trade Terminology for vending machine dolly

Key Technical Properties of Vending Machine Dollies

When selecting a vending machine dolly, understanding its technical properties is crucial for ensuring efficiency and safety in operations. Here are some essential specifications that B2B buyers should consider:

-

Material Grade

The material used in the construction of a vending machine dolly significantly affects its durability and load-bearing capacity. Common materials include steel, aluminum, and high-strength plastic. Steel offers robustness and longevity, making it ideal for heavy loads, while aluminum provides a lightweight alternative for easier maneuverability. -

Load Capacity

Defined as the maximum weight a dolly can safely carry, load capacity is a critical specification. Most vending machine dollies have a load capacity ranging from 200 to 1,500 pounds. Buyers should assess their specific needs based on the size and weight of the vending machines being moved. Investing in a dolly with an appropriate load capacity ensures operational safety and reduces the risk of equipment failure. -

Wheel Size and Type

The size and type of wheels on a dolly impact its mobility and handling. Larger wheels typically offer better performance on uneven surfaces, while smaller wheels may provide better maneuverability in tight spaces. Consideration of wheel material—such as rubber, plastic, or polyurethane—also affects durability and grip, especially when transporting heavy vending machines across diverse terrains. -

Dimensions and Weight

The overall dimensions (length, width, height) and weight of the dolly are important for storage and transport. A compact dolly can be easier to store and transport between locations, while a heavier unit may provide better stability during use. Buyers should evaluate their operating environment to choose a dolly that fits well within their logistics framework. -

Foldability and Portability

Many modern dollies feature foldable designs that enhance portability and convenience. A foldable dolly can be easily stored when not in use, which is particularly beneficial for businesses with limited space. This feature is also advantageous for companies that operate in multiple locations, allowing for simpler transport of equipment.

Common Trade Terms in the Vending Machine Dolly Industry

Understanding industry-specific terminology is essential for effective communication and negotiation in B2B transactions. Here are some common terms that buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of vending machine dollies, knowing the OEM can help buyers identify quality standards and manufacturing capabilities, essential for ensuring compatibility with existing equipment. -

MOQ (Minimum Order Quantity)

This term denotes the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory effectively and negotiate better pricing terms. For instance, if a supplier has a MOQ of 50 units, bulk purchasing may lead to cost savings. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. For buyers looking to procure vending machine dollies, issuing an RFQ can facilitate competitive pricing and better terms, enabling informed decision-making. -

Incoterms (International Commercial Terms)

These are a series of predefined commercial terms published by the International Chamber of Commerce. They are used in international trade to clarify the responsibilities of buyers and sellers. Familiarity with Incoterms helps B2B buyers understand shipping arrangements, risk management, and cost implications, ensuring smoother transactions across borders. -

Lead Time

The lead time is the duration it takes from placing an order to receiving the product. Understanding lead times is essential for effective inventory management, particularly for businesses that rely on timely delivery for operational efficiency. Buyers should inquire about lead times when negotiating with suppliers to align procurement with operational needs.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make more informed purchasing decisions regarding vending machine dollies, ultimately enhancing their operational capabilities.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine dolly Sector

Market Overview & Key Trends

The vending machine dolly sector is experiencing dynamic shifts driven by technological advancements and changing consumer behaviors. Key global drivers include the growth of e-commerce, which has intensified the demand for efficient logistics solutions. B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of the increasing integration of automation and smart technology in dolly designs, enhancing efficiency in vending machine servicing and product distribution.

Emerging trends indicate a rising preference for lightweight, durable materials that improve maneuverability while reducing operational fatigue. Innovations such as foldable and customizable dollies are gaining traction, catering to varied market needs. In Europe, for example, the focus on urban logistics is prompting manufacturers to offer products specifically designed for compact spaces. Meanwhile, buyers in Africa and South America can leverage local manufacturing partnerships to tap into unique market demands, reducing lead times and shipping costs.

Illustrative Image (Source: Google Search)

Furthermore, the emphasis on digital transformation is reshaping sourcing strategies. B2B platforms are becoming essential for connecting suppliers and buyers, allowing for greater transparency and better decision-making. Buyers are encouraged to leverage these platforms to access a broader range of suppliers, compare prices, and evaluate product specifications effectively.

Sustainability & Ethical Sourcing in B2B

As sustainability becomes a cornerstone of corporate responsibility, the vending machine dolly sector must adapt to meet environmental standards. The environmental impact of production and logistics cannot be overstated; thus, B2B buyers should prioritize suppliers that implement sustainable practices throughout their supply chains. This includes the use of recycled materials and energy-efficient manufacturing processes.

Ethical sourcing is increasingly important, as consumers and businesses alike demand transparency regarding the origins of products. Buyers should seek partners that adhere to fair labor practices and demonstrate a commitment to reducing their carbon footprint. Certifications such as FSC (Forest Stewardship Council) for wood products or ISO 14001 for environmental management can serve as benchmarks for selecting suppliers.

Incorporating ‘green’ materials, such as bioplastics or sustainably sourced metals, is not only beneficial for the environment but can also enhance brand reputation. As consumers become more eco-conscious, aligning purchasing decisions with sustainable practices can provide a competitive advantage in the marketplace.

Brief Evolution/History

The vending machine dolly has evolved significantly since its inception, originally designed for basic transport tasks in retail environments. In recent decades, advancements in materials science and ergonomic design have transformed dolly functionality. The introduction of lightweight alloys and polymers has enhanced durability while reducing weight, making them easier to handle.

Historically, the market has seen a shift from manual to semi-automated solutions, reflecting broader trends in logistics and supply chain management. The modern dolly, equipped with smart technology features, caters to the fast-paced demands of today’s retail and service sectors. This evolution not only highlights the importance of innovation but also underscores the necessity for B2B buyers to remain informed about technological advancements to maintain a competitive edge.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of vending machine dolly

-

What factors should I consider when vetting suppliers for vending machine dollies?

When vetting suppliers, prioritize their experience in the industry, production capacity, and reputation. Check for reviews and testimonials from other B2B buyers, particularly those in your region. It’s also essential to assess their compliance with international standards and regulations. Request samples to evaluate product quality firsthand. Establish communication protocols to ensure responsiveness and clarity through the sourcing process, which can help prevent misunderstandings later. -

Can I customize the vending machine dolly to fit my specific needs?

Yes, many suppliers offer customization options for vending machine dollies. This can include modifications in size, material, and design features to cater to specific vending machines or operational needs. When discussing customization, clearly outline your requirements and ask for examples of previous custom projects. Keep in mind that customization may affect lead times and pricing, so factor this into your procurement strategy. -

What is the typical minimum order quantity (MOQ) for vending machine dollies?

MOQs can vary significantly based on the supplier and the complexity of the product. Generally, for vending machine dollies, MOQs range from 50 to 200 units. It’s important to clarify these numbers before proceeding, as lower MOQs may be available, especially if you are willing to pay a premium. Understanding the MOQ helps in budgeting and managing inventory effectively, particularly in markets with fluctuating demand.

Illustrative Image (Source: Google Search)

-

What are the usual lead times for ordering vending machine dollies?

Lead times depend on factors such as the supplier’s location, production capacity, and whether you require customization. Standard lead times can range from 4 to 12 weeks, with custom orders potentially extending these timelines. To ensure timely delivery, communicate your deadlines upfront and consider suppliers who can provide a clear production schedule. Establishing a good relationship with your supplier can also facilitate quicker responses and updates throughout the process. -

What quality assurance certifications should I look for when sourcing vending machine dollies?

Look for certifications that demonstrate compliance with international safety and quality standards, such as ISO 9001 or CE marking in Europe. Additionally, check for industry-specific certifications that may apply in your region. Request documentation to verify these certifications, as they can provide assurance of the product’s quality and reliability. Quality assurance protocols not only protect your investment but also enhance your brand’s reputation in the market. -

How should I approach logistics and shipping when sourcing vending machine dollies internationally?

When sourcing internationally, consider the total landed cost, which includes shipping, tariffs, and taxes. Work with suppliers who have experience in your region to navigate local customs regulations. Opt for reliable logistics partners to ensure timely and safe delivery. It’s also beneficial to discuss shipping terms (e.g., FOB, CIF) to understand your responsibilities and mitigate risks during transportation. -

What steps can I take to resolve disputes with suppliers?

Establish clear communication channels and maintain documentation of all agreements and transactions to minimize misunderstandings. If a dispute arises, engage in direct discussions with the supplier to reach an amicable solution. If necessary, consider mediation or arbitration as a formal means of resolution. Knowing the legal framework in your region and that of the supplier can also help in effectively addressing disputes through proper channels. -

Are there specific payment terms I should negotiate with suppliers?

Negotiate payment terms that balance risk and cash flow. Common practices include a deposit upfront (10-30%) with the remainder due upon delivery or prior to shipment. For larger orders, consider letter of credit (LC) arrangements for added security. Ensure that payment methods align with your financial practices and that you understand any potential fees or currency exchange implications. Clear payment terms can help foster trust and smooth transactions with your supplier.

Strategic Sourcing Conclusion and Outlook for vending machine dolly

The strategic sourcing of vending machine dollies presents a myriad of opportunities for international buyers. As businesses seek to optimize logistics and enhance operational efficiency, understanding the nuances of sourcing from different regions becomes paramount. Key takeaways include the importance of evaluating local suppliers for reliability, quality, and cost-effectiveness. Additionally, leveraging regional trade agreements can significantly reduce tariffs and improve supply chain efficiency.

Value of Strategic Sourcing

Investing time in strategic sourcing not only reduces costs but also fosters long-term partnerships with suppliers. This approach allows businesses to remain agile, adapting to market shifts while ensuring the availability of high-quality equipment. For buyers in Africa, South America, the Middle East, and Europe, this means aligning procurement strategies with regional strengths and supplier capabilities.

Looking Forward

As the vending industry evolves, staying ahead of trends such as automation and sustainability will be crucial. International buyers should actively explore innovative solutions that enhance operational efficiency. Embrace the opportunity to network with suppliers and industry experts, and begin the journey of strategic sourcing today. The right dolly can make a significant difference in your logistics operations, empowering your business to thrive in a competitive marketplace.