Your Ultimate Guide to Sourcing Skittles Vending Machine

Guide to Skittles Vending Machine

- Introduction: Navigating the Global Market for skittles vending machine

- Understanding skittles vending machine Types and Variations

- Key Industrial Applications of skittles vending machine

- Strategic Material Selection Guide for skittles vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for skittles vending machine

- Comprehensive Cost and Pricing Analysis for skittles vending machine Sourcing

- Spotlight on Potential skittles vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for skittles vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the skittles vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of skittles vending machine

- Strategic Sourcing Conclusion and Outlook for skittles vending machine

Introduction: Navigating the Global Market for skittles vending machine

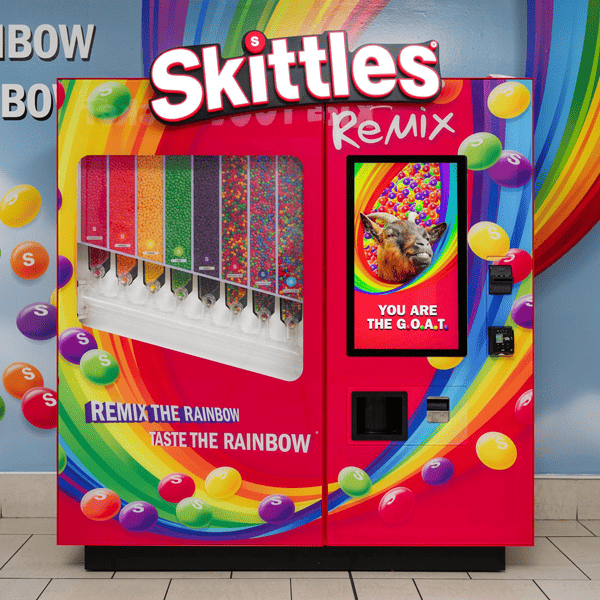

In a world increasingly driven by convenience and instant gratification, the Skittles vending machine stands out as a vibrant and engaging solution for businesses seeking to enhance customer experience and drive sales. This unique vending option not only attracts attention with its colorful display but also taps into the growing trend of automated retail, making it an ideal investment for various sectors, including entertainment venues, shopping malls, and corporate offices.

As international B2B buyers from diverse markets such as Africa, South America, the Middle East, and Europe look for innovative ways to cater to consumer demands, understanding the nuances of skittles vending machines becomes critical. This guide serves as a comprehensive resource, covering essential aspects such as the various types of machines available, materials used in manufacturing, quality control measures, key suppliers, pricing structures, and market trends.

By navigating this guide, buyers will empower themselves to make informed sourcing decisions, ensuring they select vending machines that not only meet their operational needs but also resonate with their target audience. Whether you are entering the vending space for the first time or looking to upgrade your existing offerings, this guide will equip you with actionable insights and strategies tailored for your market, enabling you to harness the full potential of skittles vending machines in your business operations.

Understanding skittles vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Floor Model | Large capacity, accessible, typically coin-operated | Shopping malls, schools, events | High visibility and capacity, but requires significant space |

| Compact Desktop Model | Smaller footprint, often electric or battery-operated | Offices, small retail locations | Space-efficient and easy to move, but limited candy variety |

| Smart Vending Machine | Equipped with digital payment and inventory tracking | Airports, tech hubs, urban areas | Enhanced customer experience and data analytics, but higher initial cost |

| Customizable Branding Model | Allows for personalized exterior and product selection | Trade shows, branded events | Strong marketing potential, but longer lead times for production |

| Multi-Product Dispenser | Offers various types of candy and snacks in one unit | Convenience stores, hotels | Versatile product offering, but may require more maintenance |

Traditional Floor Model

The traditional floor model of skittles vending machines is characterized by its large capacity and accessibility, making it ideal for high-traffic areas such as shopping malls and schools. These machines typically operate using coins, making them straightforward for consumers. For B2B buyers, the key consideration is the space required for installation, as these models can be quite large. They offer high visibility and the potential for significant sales volume but necessitate regular maintenance and restocking.

Compact Desktop Model

Compact desktop models are designed for smaller spaces, often powered by electricity or batteries. This variation is particularly suitable for offices and small retail locations where space is at a premium. B2B buyers should consider the limited candy variety offered by these machines, which may not meet the demands of larger groups. However, their portability and ease of use make them an attractive option for businesses looking to provide snacks without committing to a large-scale installation.

Smart Vending Machine

Smart vending machines represent a technological advancement in vending solutions, featuring digital payment options and inventory tracking systems. These machines are particularly effective in urban areas, airports, and tech hubs where consumers expect a seamless purchasing experience. B2B buyers should weigh the initial investment against the potential for improved customer engagement and data insights. While the upfront costs can be higher, the long-term benefits of enhanced customer experience and operational efficiency can justify the expense.

Customizable Branding Model

Customizable branding models allow businesses to personalize the exterior and product selection of the vending machine. This type is especially beneficial for trade shows and branded events where companies want to enhance their visibility and marketing efforts. B2B buyers should consider the longer lead times associated with customization, but the marketing potential can significantly outweigh this drawback, especially for companies looking to create a memorable brand experience.

Multi-Product Dispenser

Multi-product dispensers are versatile machines that offer a variety of candies and snacks in a single unit. They are commonly found in convenience stores and hotels, providing customers with more choices. For B2B buyers, the adaptability of these machines can lead to increased sales opportunities. However, they may require more maintenance and restocking to keep up with diverse product offerings. Buyers should assess the potential for higher sales against the operational demands of these units.

Related Video: How to Make OREO and Skittles Vending Machine

Key Industrial Applications of skittles vending machine

| Industry/Sector | Specific Application of Skittles Vending Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | In-store candy sales | Increases foot traffic and impulse purchases | Machine durability, product variety, payment options |

| Events and Entertainment | Concessions at venues | Enhances customer experience, boosts revenue | Size, portability, branding options |

| Educational Institutions | Snack stations in schools | Provides convenient access to treats, encourages sales | Compliance with health regulations, machine safety |

| Corporate Offices | Break room vending solutions | Improves employee satisfaction and morale | Customization, healthy snack options |

| Hospitality | Guest amenities in hotels | Adds value to guest experience, encourages repeat visits | Aesthetic appeal, maintenance support |

Retail Sector

In retail, Skittles vending machines can be strategically placed near checkout lines or high-traffic areas to drive impulse purchases. These machines can significantly increase foot traffic, as shoppers are often drawn to colorful, branded displays. For international buyers, especially in regions like Africa and South America, sourcing machines that are durable and capable of handling high temperatures is crucial. Additionally, offering a variety of product sizes can cater to diverse consumer preferences and maximize sales potential.

Events and Entertainment

At events and entertainment venues, Skittles vending machines serve as a popular concession option, appealing to audiences of all ages. They enhance the overall customer experience by providing easy access to snacks during events, which can increase overall revenue. Buyers from the Middle East and Europe should consider the machine’s portability and ease of branding, as well as its ability to handle large crowds efficiently. Ensuring that machines are stocked with popular flavors can also boost sales during peak times.

Educational Institutions

In schools and universities, Skittles vending machines can be installed in common areas to provide students with convenient access to snacks. This not only generates additional revenue for the institution but also encourages students to purchase snacks between classes. Buyers in Africa and South America must ensure that machines comply with local health regulations regarding snack offerings. Additionally, safety features should be a priority to protect young users.

Corporate Offices

For corporate offices, Skittles vending machines can enhance break rooms by providing employees with a fun and rewarding snack option. This can lead to improved employee satisfaction and morale, contributing to a positive workplace culture. International buyers should focus on customization options that allow branding to align with corporate identity. Offering a mix of healthy snacks alongside traditional options can also cater to diverse employee preferences and dietary restrictions.

Hospitality Sector

In the hospitality industry, Skittles vending machines can be utilized as part of guest amenities in hotels, adding a unique touch to the guest experience. By placing these machines in lobbies or near elevators, hotels can encourage guests to indulge in treats during their stay, which can lead to repeat visits. Buyers should prioritize aesthetic appeal and maintenance support to ensure the machines align with the hotel’s overall ambiance and operational needs.

Strategic Material Selection Guide for skittles vending machine

When selecting materials for skittles vending machines, international B2B buyers must consider various factors that affect performance, durability, and compliance with local regulations. Here, we analyze four common materials used in the construction of these machines: stainless steel, ABS plastic, tempered glass, and aluminum. Each material has unique properties and implications for application, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance and high strength-to-weight ratio. It can withstand a wide range of temperatures and pressures, making it suitable for various environments.

Pros & Cons: The durability of stainless steel is one of its primary advantages, as it can endure harsh conditions and resist rust. However, it is generally more expensive than other materials, which can impact overall project budgets. Manufacturing complexity is moderate, as stainless steel requires specialized techniques for cutting and welding.

Impact on Application: Stainless steel is highly compatible with food-grade applications, ensuring that it meets health and safety standards. Its resistance to corrosion makes it ideal for vending machines that may be exposed to moisture or cleaning agents.

Considerations for International Buyers: Buyers must ensure that the stainless steel used complies with local standards, such as ASTM in the U.S. and DIN in Europe. Additionally, sourcing from reputable suppliers is crucial to guarantee quality and compliance with food safety regulations.

ABS Plastic

Key Properties: ABS plastic is lightweight and has good impact resistance, making it a popular choice for vending machine components. It can handle moderate temperatures but is less resistant to extreme heat compared to metals.

Pros & Cons: The primary advantage of ABS plastic is its cost-effectiveness and ease of manufacturing, allowing for intricate designs and rapid production. However, it may not be as durable as metals and can be susceptible to UV degradation over time.

Impact on Application: ABS plastic is suitable for internal components and outer casings of vending machines, offering good protection for the contents. However, its lower temperature resistance may limit its use in regions with extreme climates.

Considerations for International Buyers: Buyers should verify that the ABS plastic used meets local safety and environmental regulations, particularly in regions with strict plastic use guidelines. Understanding the recyclability of ABS is also essential for compliance with sustainability initiatives.

Tempered Glass

Key Properties: Tempered glass is known for its strength and safety features, as it is designed to shatter into small, blunt pieces rather than sharp shards. It has excellent optical clarity and can withstand significant temperature fluctuations.

Pros & Cons: The aesthetic appeal of tempered glass enhances the visual merchandising of vending machines, attracting customers. However, it is heavier and more fragile than other materials, which can complicate installation and increase shipping costs.

Impact on Application: Tempered glass is ideal for display panels in vending machines, providing visibility while protecting the contents. Its safety features make it suitable for public spaces, reducing the risk of injury.

Considerations for International Buyers: Compliance with local safety standards is critical when using tempered glass, especially in public areas. Buyers should also consider the logistics of transporting glass, as it requires careful handling to prevent breakage.

Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It is easy to machine and can be anodized for additional protection, enhancing its durability.

Pros & Cons: The lightweight nature of aluminum makes it easy to transport and install, which is a significant advantage for vending machine manufacturers. However, it may not offer the same level of strength as stainless steel, potentially limiting its use in high-traffic areas.

Impact on Application: Aluminum is suitable for structural components and frames of vending machines, providing a balance between weight and strength. It is compatible with various environments, including those with high humidity.

Considerations for International Buyers: Buyers should ensure that aluminum components meet local standards, such as JIS in Japan and ASTM in the U.S. Additionally, understanding the alloy grades used can impact the overall performance and durability of the vending machines.

| Material | Typical Use Case for skittles vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, outer casing | Excellent corrosion resistance | Higher cost compared to other materials | High |

| ABS Plastic | Internal components, outer casings | Cost-effective, easy to manufacture | Less durable, susceptible to UV damage | Low |

| Tempered Glass | Display panels | Aesthetic appeal, safety features | Heavier, more fragile | Medium |

| Aluminum | Structural frames, lightweight components | Lightweight, good corrosion resistance | Lower strength compared to stainless steel | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for skittles vending machine

Manufacturing Processes for Skittles Vending Machines

The manufacturing of Skittles vending machines involves several critical stages, each contributing to the overall functionality, reliability, and aesthetic appeal of the final product. Understanding these processes is vital for B2B buyers who are looking to source high-quality machines.

1. Material Preparation

The first stage in the manufacturing process is material preparation. This involves sourcing high-quality raw materials such as metal, plastic, and electronic components.

- Key Techniques:

- Material Selection: Suppliers should prioritize durable and non-corrosive materials for increased longevity, especially in diverse environmental conditions found in Africa, South America, the Middle East, and Europe.

- Pre-treatment Processes: Techniques like galvanization or powder coating may be employed to enhance the durability of metal components against rust and wear.

2. Forming

In the forming stage, materials are shaped into the necessary components of the vending machine.

- Key Techniques:

- CNC Machining: Computer Numerical Control (CNC) machining is commonly used to ensure precision in cutting and shaping metal parts.

- Injection Molding: This technique is critical for producing plastic components with intricate designs, which are essential for the aesthetic aspects of the vending machine.

3. Assembly

The assembly process is where various components are brought together to create the final product.

- Key Techniques:

- Automated Assembly Lines: Automation enhances efficiency and consistency in assembling parts, significantly reducing labor costs and time.

- Quality Fixtures: Use of jigs and fixtures ensures that all components fit perfectly, which is crucial for machine performance.

4. Finishing

The finishing stage involves applying final touches to the vending machine. This may include painting, polishing, or adding decals.

- Key Techniques:

- Surface Treatment: Techniques such as anodizing or powder coating improve the machine’s appearance and resistance to wear.

- Final Inspection: Each unit undergoes a thorough visual inspection to check for aesthetic defects before being packaged for shipping.

Quality Assurance in Manufacturing

Quality assurance is paramount in ensuring that the Skittles vending machines meet international standards and customer expectations.

Relevant International Standards

B2B buyers should be familiar with various international quality standards that manufacturers may comply with:

- ISO 9001: This standard focuses on quality management systems and is critical for ensuring consistent quality across production processes.

- CE Marking: Required for products sold within the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Certification: Relevant in certain markets, API (American Petroleum Institute) standards may apply if the vending machines incorporate components that interact with food products.

Quality Control Checkpoints

Quality control (QC) is integrated throughout the manufacturing process, ensuring that defects are caught early and do not reach the end customer.

- Incoming Quality Control (IQC): This checkpoint occurs at the beginning of the manufacturing process, where raw materials are inspected for quality and compliance with specifications.

- In-Process Quality Control (IPQC): During assembly, random sampling and inspections are carried out to ensure that processes are followed correctly, and the components are functioning as intended.

- Final Quality Control (FQC): At this stage, the completed vending machines are tested extensively to ensure they operate correctly and meet all quality standards before shipping.

Common Testing Methods

B2B buyers should be aware of the common testing methods employed during QC:

- Functional Testing: Ensures that the vending machine operates as intended, including dispensing mechanisms and electronic components.

- Load Testing: Assesses whether the machine can handle the weight and volume of Skittles it is designed to dispense.

- Environmental Testing: Measures the machine’s performance under various environmental conditions, such as temperature and humidity variations.

Verifying Supplier Quality Control

For international B2B buyers, it is crucial to verify the quality control practices of potential suppliers to ensure they meet the necessary standards.

- Audits: Conducting on-site audits can provide insights into the supplier’s manufacturing processes and quality assurance practices. This includes reviewing documentation and observing operations firsthand.

- Quality Reports: Requesting detailed QC reports from suppliers can help buyers understand the frequency of inspections, testing methods used, and any issues encountered during manufacturing.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes and product quality, adding an additional layer of assurance.

Quality Control and Certification Nuances

Understanding the nuances of QC and certification is essential for international buyers, especially those from Africa, South America, the Middle East, and Europe:

- Regional Standards: Different regions may have specific regulations that affect the certification process. For example, European buyers should be well-versed in CE marking requirements, while buyers in the Middle East may need to comply with local health and safety standards.

- Documentation: Buyers should ensure that suppliers provide all necessary documentation, including certificates of conformity, test reports, and calibration certificates for testing equipment.

- Cultural Considerations: Engaging with suppliers from different cultural backgrounds may require understanding their business practices and quality expectations, which can vary significantly.

By thoroughly understanding the manufacturing processes and quality assurance standards, B2B buyers can make informed decisions when sourcing Skittles vending machines, ensuring they select suppliers that meet their quality expectations and regional requirements.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for skittles vending machine Sourcing

When sourcing Skittles vending machines, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis will outline the key components of cost, the factors influencing prices, and provide actionable tips for effective negotiations.

Cost Components

-

Materials: The primary materials for Skittles vending machines include high-quality plastics for the casing, glass or acrylic for the display, and mechanical components for the dispensing mechanism. Sourcing these materials from suppliers that provide certifications for quality and sustainability can impact costs significantly.

-

Labor: Labor costs will vary by region. In countries with higher wages, such as Germany, labor costs may constitute a larger portion of the manufacturing expenses compared to regions in Africa or South America. It’s essential to consider both direct labor for assembly and indirect labor for support functions like engineering and administration.

-

Manufacturing Overhead: This includes the fixed and variable costs associated with running a manufacturing facility, such as utilities, rent, and equipment maintenance. Understanding the overhead structure of your supplier can provide insight into their pricing model.

-

Tooling: If customization is required, tooling costs can be significant. This includes the expense of creating molds and fixtures necessary for producing unique designs. Buyers should inquire about these costs early in the negotiation process.

Illustrative Image (Source: Google Search)

-

Quality Control (QC): Implementing rigorous QC processes is vital, especially for machines handling food products. The cost of QC can add to the overall price, but it is essential for ensuring compliance with safety standards and maintaining product reliability.

-

Logistics: Transportation costs can vary widely based on the shipping method, distance, and Incoterms agreed upon. For international buyers, understanding the implications of different shipping options can lead to significant savings.

-

Margin: Suppliers typically incorporate a profit margin that reflects the perceived value of their products and services. This margin can be influenced by the supplier’s market position and competitive landscape.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing. Ordering larger quantities often leads to lower per-unit costs. Buyers should assess their sales forecasts to negotiate advantageous terms.

-

Specifications/Customization: Customized machines may incur additional costs due to design and tooling requirements. Buyers should be clear about their needs to avoid unexpected expenses.

-

Material Quality/Certifications: Higher-quality materials and certified products often come at a premium. However, investing in quality can reduce long-term maintenance and operational costs.

-

Supplier Factors: The supplier’s location, reputation, and production capacity can influence pricing. Engaging with multiple suppliers can help benchmark prices and terms.

-

Incoterms: The choice of Incoterms can greatly affect total costs. For example, choosing DDP (Delivered Duty Paid) can simplify logistics for buyers unfamiliar with import duties and local regulations.

Buyer Tips

-

Negotiation: Equip yourself with data on market prices and competitor offerings to negotiate effectively. Building a rapport with suppliers can also lead to better terms.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider factors like maintenance, energy consumption, and potential downtime.

-

Pricing Nuances: International buyers should be aware of currency fluctuations and their potential impact on pricing. Locking in prices and terms can mitigate risks associated with exchange rate volatility.

-

Local Regulations: Understand the regulatory environment in your region. Compliance with local health and safety standards may necessitate specific features or certifications.

-

Market Research: Conduct thorough market research to identify reputable suppliers and understand regional pricing trends. Engaging with local partners can provide valuable insights into the market dynamics.

Disclaimer

The prices and cost components discussed are indicative and can vary based on specific circumstances, supplier relationships, and market conditions. It is advisable to conduct due diligence when engaging with suppliers to ensure accurate and competitive pricing.

Spotlight on Potential skittles vending machine Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for skittles vending machine.)*

Essential Technical Properties and Trade Terminology for skittles vending machine

Key Technical Properties of Skittles Vending Machines

When considering the purchase of skittles vending machines, understanding the essential technical specifications can significantly impact operational efficiency and product longevity. Here are some critical properties to evaluate:

-

Material Grade

– Definition: This refers to the type of materials used in the construction of the vending machine, such as stainless steel, ABS plastic, or tempered glass.

– Importance: High-grade materials enhance durability and resistance to corrosion, especially in humid environments like those found in Africa and South America. Choosing the right material can minimize maintenance costs and extend the machine’s lifespan. -

Capacity

– Definition: The volume or quantity of Skittles that the machine can hold, usually measured in kilograms or liters.

– Importance: A larger capacity is essential for high-traffic areas where demand is significant. Understanding the capacity allows businesses to match their supply with customer demand effectively, reducing the frequency of restocking. -

Dispensing Mechanism

– Definition: The technology used to dispense Skittles, which can vary from gravity-fed systems to electronic mechanisms.

– Importance: Efficient dispensing mechanisms reduce jams and ensure a smooth customer experience. Evaluating the reliability of these systems can prevent loss of sales due to machine malfunctions. -

Power Requirements

– Definition: Specifications regarding the voltage and wattage needed to operate the vending machine.

– Importance: Understanding power requirements is crucial for installation, especially in regions with varying electrical standards. Ensuring compatibility can avoid operational downtimes and additional costs associated with electrical upgrades. -

Connectivity Features

– Definition: This includes options for cashless payment systems, such as credit/debit card readers and mobile payment solutions.

– Importance: In an increasingly digital economy, offering diverse payment options can enhance customer convenience and increase sales volume. Machines equipped with modern connectivity features are more attractive to tech-savvy consumers. -

Size and Weight

– Definition: The dimensions and weight of the vending machine, which affect placement and transportation.

– Importance: Knowing the size and weight is vital for logistical planning and ensures the machine fits in designated spaces without obstructing traffic. This is especially relevant in crowded urban settings.

Common Trade Terminology

Familiarity with industry terminology can facilitate smoother transactions and enhance understanding between buyers and suppliers. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers evaluate the quality and reliability of the machines, as well as the availability of spare parts. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units that a supplier is willing to sell.

– Importance: Knowing the MOQ is crucial for budgeting and inventory management. It helps buyers avoid over-purchasing and ensures that they meet supplier requirements for order fulfillment. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to solicit price quotes from suppliers for specific products or services.

– Importance: Using RFQs effectively can lead to better pricing and terms. It enables buyers to compare offers from multiple suppliers, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A series of pre-defined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers.

– Importance: Understanding Incoterms is vital for international trade as they define who is responsible for shipping, insurance, and tariffs. This knowledge helps prevent disputes and ensures clear expectations. -

Lead Time

– Definition: The time taken from placing an order to its delivery.

– Importance: Knowing lead times helps businesses plan their operations and inventory levels effectively. It’s essential for maintaining customer satisfaction by ensuring product availability. -

Warranty and Service Level Agreement (SLA)

– Definition: A warranty is a guarantee provided by the manufacturer regarding the performance of the machine, while an SLA outlines the expected service levels post-purchase.

– Importance: These agreements protect buyers against manufacturing defects and service shortfalls, providing peace of mind and ensuring operational continuity.

By grasping both the technical properties and industry terminology, B2B buyers can make informed decisions that align with their operational needs and market conditions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the skittles vending machine Sector

Market Overview & Key Trends

The global skittles vending machine sector is experiencing robust growth, driven by a combination of evolving consumer preferences, advancements in technology, and a shift toward automated retail solutions. In regions such as Africa and South America, the demand for convenience and instant gratification is rising, prompting businesses to invest in vending solutions that offer a diverse range of products, including popular candy brands like Skittles. In Europe and the Middle East, the focus is increasingly on personalized vending experiences, facilitated by digital payment systems and smart vending machines that utilize data analytics to optimize product offerings based on consumer behavior.

Emerging trends in sourcing include a notable shift towards local suppliers and manufacturers. International buyers are recognizing the benefits of reducing supply chain risks and enhancing responsiveness to market changes. Additionally, the integration of IoT technology in vending machines is becoming prevalent, allowing operators to monitor inventory levels in real-time and streamline replenishment processes. This technological advancement not only improves operational efficiency but also enhances customer satisfaction by minimizing out-of-stock scenarios.

Illustrative Image (Source: Google Search)

As competition intensifies in the vending sector, international buyers must remain vigilant to market dynamics, such as fluctuating raw material costs and regulatory changes. Understanding regional preferences and adapting product assortments accordingly can provide a competitive edge. For instance, while Skittles may be universally recognized, regional flavor adaptations could significantly enhance market penetration in diverse locales.

Sustainability & Ethical Sourcing in B2B

Sustainability is a critical consideration for B2B buyers in the skittles vending machine sector. Environmental impacts associated with vending operations, such as energy consumption and plastic waste, are under increasing scrutiny. Buyers are encouraged to seek vending machines that utilize energy-efficient technologies and sustainable materials. For instance, machines made with recyclable components not only reduce the carbon footprint but also resonate with environmentally conscious consumers.

The importance of ethical supply chains cannot be overstated. B2B buyers should prioritize partnerships with suppliers who adhere to fair labor practices and transparent sourcing. This commitment not only enhances brand reputation but also aligns with the growing consumer preference for ethically sourced products. Certifications such as Fair Trade and eco-labels can serve as valuable indicators of a supplier’s commitment to sustainability.

Furthermore, incorporating ‘green’ materials into the vending machine design, such as biodegradable plastics or recycled metals, can contribute to a company’s sustainability goals. As regulatory frameworks around waste management and emissions tighten globally, investing in sustainable vending solutions will not only meet legal requirements but also position businesses favorably in the eyes of eco-conscious consumers.

Brief Evolution/History

The evolution of vending machines, particularly those dispensing confectionery like Skittles, traces back to the late 1880s when the first mechanical vending machines were introduced in Europe. Initially, these machines offered simple products like postcards and stamps. However, as technology advanced, the range of offerings expanded significantly, culminating in the modern vending machines we see today, which feature interactive screens and cashless payment options.

With the rise of the snack culture in the late 20th century, vending machines became a staple in locations such as schools, offices, and public spaces, catering to the growing demand for on-the-go snacks. The introduction of Skittles into vending machines has been particularly successful due to their colorful branding and widespread appeal, making them a go-to choice for consumers seeking quick indulgence. Today, the focus is not only on convenience but also on integrating sustainability and technology, reflecting the evolving preferences of the global market.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of skittles vending machine

-

What key factors should I consider when vetting suppliers for Skittles vending machines?

When vetting suppliers, prioritize their experience in the vending machine industry and any specific expertise with confectionery products. Check for certifications that align with international standards, such as ISO or CE compliance, indicating quality and safety. Request references from previous clients, especially those in your target market, and assess their responsiveness and customer support. Additionally, evaluate their production capacity and lead times to ensure they can meet your demands without delays. -

Can I customize the Skittles vending machines for my market?

Yes, many suppliers offer customization options for Skittles vending machines. This can include branding with your company logo, color schemes that resonate with local preferences, and even specific configurations to accommodate different Skittles flavors. When discussing customization, be clear about your requirements and inquire about the associated costs and lead times. Ensure that the supplier has a proven track record of delivering customized machines to avoid potential pitfalls. -

What is the typical minimum order quantity (MOQ) for Skittles vending machines, and how does it affect pricing?

The MOQ for Skittles vending machines can vary significantly by supplier, often ranging from 10 to 100 units. Higher MOQs usually lead to lower per-unit costs, making it more economical to place larger orders if you have the demand. However, consider your market size and sales projections before committing to an MOQ. Additionally, discuss potential flexibility in MOQs with suppliers, as some may allow smaller orders for first-time buyers or test markets. -

What payment terms should I expect when sourcing Skittles vending machines internationally?

Payment terms can differ widely based on the supplier’s policies and your negotiating leverage. Common terms include a deposit upfront (often 30-50%) with the balance due upon shipment or delivery. For international transactions, consider using secure payment methods like letters of credit or escrow services to mitigate risks. Always clarify payment terms in the contract, including any penalties for late payments, to avoid disputes down the line. -

How can I ensure quality assurance and certifications for the vending machines?

To ensure quality, request documentation of the supplier’s quality assurance processes and any relevant certifications. Look for compliance with international standards, such as ISO 9001 for quality management systems. Additionally, inquire about their testing procedures for the machines and if they provide a warranty or guarantee. Conducting a factory visit or third-party inspection can also help verify that the machines meet your specifications and quality expectations. -

What logistics considerations should I keep in mind when importing Skittles vending machines?

Logistics is crucial when importing vending machines. Assess the supplier’s ability to handle shipping and customs clearance, as well as their experience with international freight. Evaluate shipping options, including air freight for faster delivery versus sea freight for cost-effectiveness. Be aware of import duties and taxes in your country, and plan for potential delays at customs. Establish a clear timeline for delivery and ensure that the supplier provides tracking information for your shipments. -

How can I resolve disputes effectively with my vending machine supplier?

To minimize disputes, establish clear communication channels and document all agreements in writing. If a dispute arises, address it promptly through direct communication with the supplier. Many suppliers are open to negotiation and may offer solutions such as refunds or replacements. If resolution efforts fail, refer to the contract for mediation or arbitration clauses. Engaging a local legal expert familiar with international trade can also provide guidance on navigating complex situations. -

What after-sales support should I expect from a Skittles vending machine supplier?

After-sales support is vital for maintaining the functionality and profitability of your vending machines. Expect suppliers to offer technical support, maintenance services, and spare parts availability. Inquire about training for your staff on machine operation and troubleshooting. Additionally, understand the warranty coverage and how claims are processed. Establishing a strong after-sales relationship with your supplier can enhance your operational efficiency and customer satisfaction in the long run.

Strategic Sourcing Conclusion and Outlook for skittles vending machine

As international B2B buyers assess the potential of Skittles vending machines, strategic sourcing emerges as a pivotal factor in capitalizing on this opportunity. By focusing on supplier reliability, product quality, and market trends, businesses can ensure a competitive edge. Key takeaways include the importance of understanding local consumer preferences, leveraging technology for inventory management, and fostering relationships with diverse suppliers across regions.

Investing in a Skittles vending machine not only diversifies product offerings but also taps into the growing demand for convenient, on-the-go snacking options. Strategic sourcing is essential to negotiate favorable terms, mitigate risks, and enhance supply chain efficiency, particularly in emerging markets in Africa and South America, as well as established markets in Europe and the Middle East.

Looking ahead, the market for vending solutions is poised for growth. International B2B buyers should act now to secure partnerships and explore innovative vending solutions that resonate with local tastes. By prioritizing strategic sourcing, you can position your business at the forefront of the evolving vending landscape, driving profitability and customer satisfaction in a competitive marketplace.