Your Ultimate Guide to Sourcing Are Vending Machines A Good

Guide to Are Vending Machines A Good Investment

- Introduction: Navigating the Global Market for are vending machines a good investment

- Understanding are vending machines a good investment Types and Variations

- Key Industrial Applications of are vending machines a good investment

- Strategic Material Selection Guide for are vending machines a good investment

- In-depth Look: Manufacturing Processes and Quality Assurance for are vending machines a good investment

- Comprehensive Cost and Pricing Analysis for are vending machines a good investment Sourcing

- Spotlight on Potential are vending machines a good investment Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for are vending machines a good investment

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the are vending machines a good investment Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of are vending machines a good investment

- Strategic Sourcing Conclusion and Outlook for are vending machines a good investment

Introduction: Navigating the Global Market for are vending machines a good investment

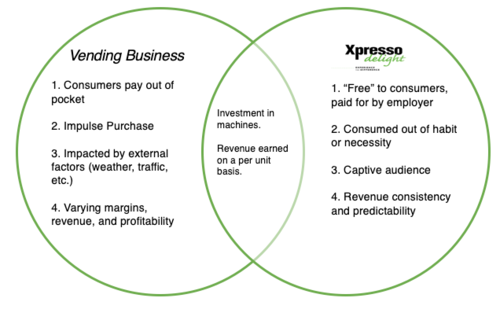

In today’s fast-paced global economy, the vending machine industry presents a unique opportunity for savvy B2B buyers looking to diversify their investment portfolios. As urbanization accelerates and consumer preferences shift towards convenience, vending machines have evolved from simple snack dispensers to sophisticated, high-tech solutions that cater to a wide array of markets. This guide aims to provide you with the insights necessary to determine whether investing in vending machines is a prudent decision for your business.

Understanding the nuances of this market is critical. We will explore various types of vending machines, including traditional, healthy, and automated options, while considering the materials used in their construction and the manufacturing quality control processes that ensure reliability and longevity. Additionally, we will identify reputable suppliers across different regions, analyze cost structures, and assess market trends that impact profitability.

With a focus on international B2B buyers from Africa, South America, the Middle East, and Europe, this guide is designed to empower you with actionable insights that facilitate informed sourcing decisions. By addressing frequently asked questions and providing a comprehensive overview of the vending machine landscape, we will equip you to navigate this promising investment opportunity with confidence. Whether you are based in Mexico, Italy, or elsewhere, understanding the dynamics of the vending machine market can lead to strategic advantages in your business operations.

Understanding are vending machines a good investment Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Snack Machines | Dispense snacks and beverages; typically coin-operated | Offices, schools, hospitals | Pros: Low maintenance, familiar to users. Cons: Limited product range, lower profit margins. |

| Healthy Vending Machines | Focus on nutritious options, often cashless or app-based | Gyms, health clubs, schools | Pros: Appeals to health-conscious consumers, higher pricing potential. Cons: Requires careful product sourcing. |

| Specialty Vending Machines | Customized for niche products (e.g., electronics, cosmetics) | Airports, hotels, retail stores | Pros: Unique offerings can attract high foot traffic. Cons: Higher upfront investment and operational complexity. |

| Automated Retail Kiosks | Larger, often touchscreen-operated machines with diverse inventory | Shopping malls, airports | Pros: Enhanced user experience, can sell a wide range of products. Cons: Higher costs and technical support needs. |

| Mobile Vending Solutions | Portable units that can be relocated as needed | Events, festivals, construction sites | Pros: Flexibility in location, can target specific events. Cons: Limited stock capacity and potential for variable sales. |

Traditional Snack Machines

Traditional snack machines are the most recognizable type, dispensing a variety of snacks and beverages. They are typically coin-operated, making them easy to install in various locations such as offices, schools, and hospitals. For B2B buyers, these machines offer a low-maintenance solution with a familiar user experience. However, the limited product range can lead to lower profit margins, so businesses must carefully consider their target audience and location to maximize sales.

Healthy Vending Machines

With a growing focus on health and wellness, healthy vending machines provide nutritious snack options, often featuring cashless or app-based payment systems. These machines are well-suited for gyms, health clubs, and schools, where health-conscious consumers are prevalent. B2B buyers should consider the sourcing of high-quality products to meet consumer expectations. While these machines can command higher prices due to their unique offerings, careful management is essential to ensure product freshness and variety.

Specialty Vending Machines

Specialty vending machines cater to niche markets by offering unique products, such as electronics, cosmetics, or gourmet food. They are often found in high-traffic locations like airports, hotels, and retail stores. For B2B buyers, investing in specialty machines can yield significant returns due to their ability to attract diverse consumer bases. However, the higher upfront investment and operational complexity necessitate thorough market research and strategic planning to ensure profitability.

Automated Retail Kiosks

Automated retail kiosks represent an evolution in vending technology, featuring larger units often equipped with touchscreens that allow for a more interactive shopping experience. They can sell a wide range of products, making them ideal for locations such as shopping malls and airports. B2B buyers should weigh the enhanced user experience and potential for diverse inventory against the higher costs and technical support requirements associated with these advanced machines.

Mobile Vending Solutions

Mobile vending solutions offer flexibility by providing portable units that can be relocated to target specific events or locations, such as festivals or construction sites. This adaptability allows businesses to capitalize on transient foot traffic and cater to diverse consumer needs. However, B2B buyers should be aware of the limited stock capacity and potential variability in sales based on location and event type, which can impact overall profitability.

Key Industrial Applications of are vending machines a good investment

| Industry/Sector | Specific Application of are vending machines a good investment | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Dispensing medical supplies and snacks | Improved patient satisfaction and convenience | Compliance with health regulations, temperature control |

| Education | Providing snacks and beverages on campus | Increased student engagement and revenue streams | Variety of product offerings, payment system flexibility |

| Corporate Offices | Offering refreshments and snacks in break rooms | Enhanced employee morale and productivity | Custom branding options, maintenance services |

| Transportation Hubs | Selling travel essentials and snacks at airports and stations | Increased foot traffic revenue | High durability, theft prevention features |

| Retail | Automated checkout solutions for convenience goods | Reduced labor costs and improved customer experience | Inventory management systems, product variety |

Healthcare Applications

In healthcare settings, vending machines can be utilized to dispense medical supplies, snacks, and beverages, thereby enhancing patient satisfaction. These machines can stock essential items like over-the-counter medications, hygiene products, and nutritious snacks, providing convenience to both patients and visitors. For international buyers in Africa and the Middle East, sourcing machines that comply with local health regulations is crucial. Additionally, temperature control features are essential for medications that require specific storage conditions, ensuring compliance with healthcare standards.

Education Applications

In educational institutions, vending machines serve as a valuable resource for providing snacks and beverages to students. This not only increases student engagement but also creates additional revenue streams for schools and universities. For buyers in South America and Europe, it is important to consider the variety of products offered, as preferences can vary significantly across regions. Flexibility in payment systems, including cashless options, is also a key consideration to cater to the tech-savvy student population.

Corporate Office Applications

Vending machines in corporate offices can significantly enhance employee morale by providing easy access to refreshments and snacks during breaks. This can lead to improved productivity and job satisfaction. For B2B buyers in Europe, custom branding options can help companies reinforce their brand identity. Additionally, sourcing machines that come with maintenance services ensures that the machines are always stocked and operational, further contributing to a positive workplace environment.

Transportation Hubs Applications

In transportation hubs such as airports and train stations, vending machines can effectively meet the needs of travelers by offering snacks and essential travel items. This application can lead to increased foot traffic and revenue for businesses operating in these high-traffic areas. International buyers should focus on sourcing machines that are highly durable and equipped with theft prevention features, as these locations often face challenges related to security and machine vandalism.

Retail Applications

Vending machines are increasingly being used in retail settings as automated checkout solutions for convenience goods. This application helps reduce labor costs while improving the customer experience by minimizing wait times. Buyers from Africa and South America should consider machines that incorporate advanced inventory management systems to ensure that popular products are always available. Additionally, offering a wide variety of products can attract diverse customer demographics, enhancing overall sales potential.

Related Video: How I Turned Vending Machines Into A $300K Business | On The Job

Strategic Material Selection Guide for are vending machines a good investment

When considering the investment in vending machines, selecting the right materials is crucial for ensuring durability, performance, and cost-effectiveness. Below is an analysis of four common materials used in vending machine construction, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its high corrosion resistance and strength, making it suitable for environments where moisture and cleaning agents are prevalent. It typically has a temperature rating of up to 800°F (427°C) and can withstand significant pressure.

Pros & Cons:

Stainless steel is highly durable and requires minimal maintenance, which is essential for vending machines that may be exposed to harsh conditions. However, it is more expensive than other materials, which can impact initial investment costs. Manufacturing complexity can also be higher due to the need for specialized equipment for cutting and welding.

Impact on Application:

Stainless steel is ideal for vending machines that dispense food and beverages, as it does not react with these products and maintains hygiene standards.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should consider compliance with food safety regulations and standards such as EN 10088. In Africa and South America, local sourcing of stainless steel may vary in quality, impacting durability.

2. Plastic (Polycarbonate)

Key Properties:

Polycarbonate is a lightweight, high-impact resistant material that can withstand temperatures up to 270°F (132°C). It is also resistant to UV radiation, making it suitable for outdoor vending machines.

Pros & Cons:

The primary advantage of polycarbonate is its cost-effectiveness and ease of manufacturing. It can be molded into various shapes, allowing for innovative designs. However, it is less durable than metals and may become discolored or brittle over time, especially in extreme weather conditions.

Impact on Application:

Polycarbonate is suitable for transparent sections of vending machines, such as display windows, allowing visibility of products while protecting them from environmental factors.

Considerations for International Buyers:

In regions like Africa and South America, where UV exposure is high, selecting high-quality polycarbonate that meets ASTM standards for UV resistance is crucial. Buyers should also be aware of local regulations regarding plastic materials.

3. Mild Steel

Key Properties:

Mild steel is a low-carbon steel known for its good weldability and formability. It typically has a temperature rating of around 600°F (316°C) and is strong yet relatively lightweight.

Pros & Cons:

Mild steel is cost-effective and widely available, making it a popular choice for vending machine frames. However, it is prone to rust and corrosion if not properly coated, which can lead to higher maintenance costs over time.

Impact on Application:

Mild steel is suitable for structural components of vending machines but may require protective coatings for longevity, especially in humid environments.

Considerations for International Buyers:

Buyers in Europe must ensure compliance with EN standards for structural steel, while those in Africa and South America should consider local environmental conditions that may affect the longevity of mild steel components.

4. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has a temperature rating of around 1,200°F (649°C). It is also an excellent conductor of heat, making it suitable for machines that require temperature regulation.

Pros & Cons:

Aluminum’s lightweight nature makes it easier to transport and install, reducing overall costs. However, it is generally more expensive than mild steel and can be less durable under heavy impacts.

Impact on Application:

Aluminum is ideal for vending machines that require mobility or frequent relocation, as its lightweight properties facilitate easy movement.

Considerations for International Buyers:

In the Middle East and Europe, compliance with aluminum standards such as EN 573 is essential. Buyers should also consider the availability of aluminum alloys that meet their specific needs.

Summary Table

| Material | Typical Use Case for are vending machines a good investment | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and beverage vending machines | Highly durable, low maintenance | Higher initial cost, complex manufacturing | High |

| Plastic (Polycarbonate) | Display windows in vending machines | Cost-effective, lightweight | Less durable, UV sensitivity | Low |

| Mild Steel | Structural components of vending machines | Cost-effective, widely available | Prone to rust, requires protective coating | Low |

| Aluminum | Mobile vending machines | Lightweight, corrosion-resistant | More expensive, less impact-resistant | Medium |

This guide provides actionable insights for international B2B buyers, helping them make informed decisions when investing in vending machines. Understanding the properties and implications of material selection can lead to better performance, reduced maintenance costs, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for are vending machines a good investment

Manufacturing Processes for Vending Machines

The manufacturing of vending machines involves several critical stages, each designed to ensure that the final product meets quality and functionality standards. Understanding these stages can help international B2B buyers make informed decisions regarding investments in vending machines.

1. Material Preparation

The first stage involves selecting and preparing the materials needed for the vending machines. Common materials include:

- Metal Alloys: Typically used for structural components due to their strength and durability.

- Plastics: Employed for panels and internal mechanisms, offering versatility and cost-effectiveness.

- Electronic Components: Such as sensors, payment systems, and controllers that are crucial for machine functionality.

During this phase, it is essential to ensure that materials comply with international standards, which can affect the overall quality and longevity of the vending machines.

2. Forming

The forming stage is where the prepared materials are shaped into components. Key techniques include:

- Stamping: Used for creating metal parts by applying high pressure to sheets of metal.

- Injection Molding: Employed for shaping plastic components by injecting molten plastic into molds.

- CNC Machining: Utilized for precision parts, ensuring that components meet exact specifications.

These methods require skilled operators and advanced machinery to maintain consistent quality and precision.

3. Assembly

In the assembly phase, the individual components come together to form the complete vending machine. This process often includes:

- Mechanical Assembly: Involves connecting parts such as doors, frames, and internal mechanisms.

- Electrical Assembly: Focuses on integrating electronic components, ensuring that wiring and connections are secure and functional.

- Software Integration: Installing and configuring the machine’s operating software, which controls payment processing and inventory management.

A well-organized assembly line can significantly enhance productivity and reduce lead times, making it critical for manufacturers targeting international markets.

4. Finishing

The finishing stage includes processes that enhance the aesthetic and protective qualities of the vending machines. Key activities involve:

- Surface Treatment: Techniques such as powder coating or painting to protect against corrosion and wear.

- Quality Checks: Final inspections to ensure that all components are correctly installed and the machine functions as intended.

Effective finishing not only improves the machine’s appearance but also extends its operational lifespan, a crucial consideration for B2B buyers.

Quality Assurance in Vending Machine Manufacturing

Quality assurance (QA) is a fundamental aspect of the manufacturing process, ensuring that vending machines meet both regulatory requirements and customer expectations. For international B2B buyers, understanding QA processes is vital for assessing potential suppliers.

International Standards

Manufacturers of vending machines often adhere to various international standards to guarantee product quality. Some of the key certifications include:

- ISO 9001: A widely recognized standard that sets out the criteria for a quality management system, focusing on customer satisfaction and continuous improvement.

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards, essential for machines sold in the European market.

- API Standards: Relevant for specific components, particularly those related to electronic and payment systems.

B2B buyers should verify that suppliers possess these certifications, as they reflect a commitment to quality and compliance.

Quality Control Checkpoints

Quality control (QC) checkpoints are essential throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Inspects raw materials and components upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitors the manufacturing process at various stages to identify and rectify issues in real-time.

- Final Quality Control (FQC): Conducts comprehensive testing of the finished product to ensure it meets all specifications and functions correctly.

Implementing robust QC checkpoints can help mitigate risks associated with product defects and ensure customer satisfaction.

Common Testing Methods

Several testing methods are employed to evaluate the functionality and safety of vending machines:

- Functional Testing: Ensures that all electronic components, including payment systems and sensors, operate as intended.

- Durability Testing: Simulates long-term use to assess the machine’s resilience against wear and tear.

- Compliance Testing: Verifies adherence to safety and regulatory standards, particularly for machines intended for international markets.

B2B buyers should inquire about the testing methods used by suppliers to ensure that the machines meet their operational requirements.

Verifying Supplier Quality Control

B2B buyers must actively verify the quality control practices of potential suppliers. Key strategies include:

- Supplier Audits: Conducting on-site audits to assess the manufacturing processes, QC checkpoints, and compliance with international standards.

- Requesting Quality Reports: Asking suppliers for detailed quality assurance reports that outline their QC processes and results.

- Third-Party Inspections: Engaging independent inspection agencies to evaluate the manufacturing facilities and processes, providing an objective assessment of quality.

By taking these steps, buyers can gain confidence in their suppliers’ ability to deliver high-quality vending machines that meet international standards.

QC and Certification Nuances for International Buyers

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is critical. Here are some considerations:

- Local Regulations: Different regions have specific regulatory requirements that may impact the certification process. Buyers should familiarize themselves with these regulations to ensure compliance.

- Cultural Differences: Manufacturing standards and practices may vary significantly between regions. Buyers should be aware of these differences when evaluating suppliers.

- Logistical Challenges: Importing machines may involve additional inspections and certifications, particularly in regions with stringent import regulations. Buyers should factor these costs and timelines into their investment decisions.

By comprehensively understanding the manufacturing processes and quality assurance measures in the vending machine industry, international B2B buyers can make informed investment decisions that align with their operational needs and market expectations.

Related Video: Most Satisfying Factory Production Processes And Heavy-Duty Factory Machines!

Comprehensive Cost and Pricing Analysis for are vending machines a good investment Sourcing

When considering the investment in vending machines, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis will cover the cost components involved, the factors influencing pricing, and actionable tips for negotiating better deals, particularly relevant for buyers from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary costs include the machine’s body, electronic components, and refrigeration units. Sourcing high-quality materials can lead to a higher initial investment but may reduce long-term maintenance and operational costs.

-

Labor: This includes costs associated with assembly, installation, and maintenance. Depending on the region, labor costs can vary significantly. Countries with higher labor costs may offer better-skilled workers, impacting the quality of the final product.

-

Manufacturing Overhead: This encompasses indirect costs like factory utilities, administrative expenses, and depreciation. Understanding the manufacturing environment of your supplier can provide insights into these costs.

-

Tooling: Customization of vending machines may require specialized tooling, which can be a significant upfront investment. If customization is necessary, buyers should factor in these costs early in the negotiation process.

-

Quality Control (QC): Ensuring that the machines meet specific quality standards can add costs. Engaging suppliers with robust QC processes may incur higher upfront costs but can save money on repairs and replacements in the long run.

-

Logistics: Shipping costs are a critical factor, especially for international buyers. This includes freight charges, insurance, and customs duties. Understanding Incoterms can help buyers clarify who bears these costs.

-

Margin: Suppliers will typically include a profit margin in their pricing. This margin can vary based on competition, brand strength, and market demand.

Price Influencers

-

Volume/MOQ: Purchasing in bulk can significantly reduce per-unit costs. Many suppliers offer discounts for larger orders, which can be beneficial for businesses planning to deploy multiple machines.

-

Specifications/Customization: Machines tailored to specific needs may come at a premium. Buyers should assess whether the benefits of customization justify the additional costs.

-

Materials: The choice of materials directly impacts the price. High-quality, durable materials may cost more initially but can lead to lower maintenance costs and longer lifespans.

-

Quality/Certifications: Machines that meet international quality standards or have certifications may be priced higher but offer assurance of reliability and compliance, which is particularly important in regulated markets.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record may charge more due to perceived quality and reliability.

-

Incoterms: Understanding shipping terms can help avoid unexpected costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can shift financial responsibilities between buyer and seller.

Buyer Tips

-

Negotiation: Effective negotiation can lead to better pricing. Buyers should be prepared to discuss volume commitments, payment terms, and potential discounts for early payment or bulk orders.

-

Cost-Efficiency: Evaluate the total cost of ownership rather than just the initial purchase price. Consider factors like energy efficiency, maintenance costs, and potential downtime.

-

Pricing Nuances: International buyers should be aware of currency fluctuations, import taxes, and regional market conditions that can affect pricing. Building relationships with suppliers can also provide leverage in negotiations.

-

Research and Comparison: Conduct thorough research and obtain multiple quotes to compare pricing and services. This helps in identifying the best value proposition.

Disclaimer

Prices and costs mentioned are indicative and can vary based on market conditions, supplier negotiations, and regional economic factors. Buyers are encouraged to conduct their own due diligence and market analysis before making purchasing decisions.

Spotlight on Potential are vending machines a good investment Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for are vending machines a good investment.)*

Essential Technical Properties and Trade Terminology for are vending machines a good investment

Key Technical Properties of Vending Machines

When considering vending machines as an investment, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications to keep in mind:

-

Material Grade: Vending machines are typically constructed from various materials such as stainless steel, plastic, and glass. Stainless steel offers durability and resistance to corrosion, making it ideal for high-traffic locations. Selecting the right material is essential for ensuring the longevity of the machine, especially in outdoor or humid environments.

-

Capacity: This refers to the number of items a vending machine can hold, which directly impacts its revenue potential. Machines can vary widely in capacity, from small units holding a few dozen items to larger models accommodating hundreds. Understanding capacity helps buyers evaluate how frequently they need to restock and the potential sales volume.

-

Power Requirements: Vending machines require a specific voltage and amperage to operate. Buyers must ensure that the electrical infrastructure at their intended installation site can support these requirements. Failing to do so could lead to additional costs for electrical upgrades, thereby affecting the overall investment.

-

User Interface: The design and functionality of the user interface can significantly influence customer experience. Modern vending machines may include touchscreens, cashless payment options, and customizable interfaces. A user-friendly design not only attracts more customers but also enhances operational efficiency.

-

Warranty and Support: A comprehensive warranty and reliable customer support from the manufacturer can save B2B buyers from costly repairs and downtime. Understanding the warranty terms is vital, as it indicates the manufacturer’s confidence in their product and their commitment to customer service.

Common Trade Terminology

Familiarity with industry jargon is essential for effective communication and negotiation in the vending machine market. Here are several key terms to know:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships is important for buyers who want to ensure quality and compatibility of replacement parts and accessories.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers assess whether a supplier can meet their needs, particularly when entering new markets or testing new products.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to solicit price quotations for specific products or services. B2B buyers should prepare detailed RFQs to ensure they receive accurate and comparable pricing, which aids in making informed purchasing decisions.

-

Incoterms (International Commercial Terms): These are international rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for buyers to know their obligations regarding shipping, insurance, and tariffs, which can significantly affect the total cost of investment.

-

Lead Time: This term refers to the amount of time it takes from placing an order to receiving the product. It is essential for B2B buyers to understand lead times to manage inventory effectively and avoid lost sales due to stock shortages.

Being knowledgeable about these technical properties and trade terms will empower B2B buyers to make strategic decisions regarding vending machine investments. Understanding these elements enhances negotiation leverage, clarifies expectations, and ultimately contributes to the success of the investment.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the are vending machines a good investment Sector

Market Overview & Key Trends

The vending machine sector is undergoing significant transformation, driven by technological advancements and changing consumer preferences. Global drivers such as urbanization, the fast-paced lifestyle of consumers, and the increasing demand for convenience are pivotal in shaping this market. For international B2B buyers from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed investment decisions.

One of the key trends is the integration of smart technology into vending machines. Features such as cashless payment options, IoT connectivity, and real-time inventory management are becoming standard. This tech-driven shift not only enhances user experience but also streamlines operations for businesses, making them more appealing to buyers. For instance, in Europe, the rise of mobile payment systems has led to increased sales, while in Africa, solar-powered vending machines are gaining traction, particularly in areas with unreliable power supply.

Additionally, the focus on personalization is reshaping product offerings. Vending machines that adapt to consumer preferences through AI and machine learning are emerging. For B2B buyers, this means sourcing machines that can cater to local tastes and dietary needs, thereby maximizing market penetration. Moreover, the growing trend of healthy eating is pushing operators to include more nutritious snack options, which presents an opportunity for suppliers to align with health-conscious brands.

Sustainability & Ethical Sourcing in B2B

As global awareness around sustainability intensifies, the vending machine sector is not exempt from this scrutiny. The environmental impact of manufacturing, operating, and disposing of vending machines necessitates a focus on sustainable practices. For B2B buyers, sourcing from manufacturers that prioritize eco-friendly materials and processes is increasingly important. This includes the use of recyclable materials in machine construction and energy-efficient components that reduce carbon footprints.

Ethical sourcing is also a vital consideration. Buyers should seek partnerships with suppliers who adhere to fair labor practices and ethical supply chains. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can guide buyers in identifying responsible vendors. Furthermore, investing in vending machines that support local products can enhance sustainability efforts while also appealing to consumers who prefer to support local economies.

Incorporating sustainability into the vending machine business model not only helps in complying with regulations but also enhances brand reputation. Companies that demonstrate a commitment to sustainable practices are more likely to attract environmentally conscious consumers, thus driving sales and fostering loyalty.

Illustrative Image (Source: Google Search)

Brief Evolution/History

The vending machine industry has evolved significantly since its inception in the early 1880s, when the first coin-operated machines dispensed simple items like postcards and cigarettes. Over the decades, the sector has transitioned to offer a wide array of products, including food and beverages, driven by technological advancements and changing consumer habits.

The introduction of electronic payment systems in the late 20th century marked a turning point, enabling consumers to purchase products conveniently. More recently, the advent of smart vending machines equipped with touchscreens, cashless payment options, and telemetry has revolutionized the industry, making it a viable investment for B2B buyers seeking innovative solutions to meet modern consumer demands.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of are vending machines a good investment

-

What factors should I consider when vetting vending machine suppliers?

When vetting vending machine suppliers, prioritize their experience and reputation in the industry. Look for suppliers with a proven track record in international markets relevant to your region, such as Africa, South America, the Middle East, and Europe. Verify their certifications and compliance with local regulations, which can vary significantly by country. Additionally, consider customer reviews and testimonials to gauge their reliability and service quality. Establishing a strong relationship with a reputable supplier can facilitate smoother transactions and better support in case of issues. -

Can I customize vending machines to cater to my local market?

Yes, many suppliers offer customization options for vending machines, allowing you to tailor them to meet the preferences of your local market. Customization can include product selection, branding, and machine features (like cashless payment systems). When negotiating with suppliers, clearly communicate your specific requirements and regional preferences. This not only enhances customer satisfaction but can also differentiate your offering in a competitive market. Ensure that the supplier has experience in customizing machines for diverse markets to avoid potential pitfalls. -

What are the typical minimum order quantities (MOQ) and lead times for vending machines?

Minimum order quantities (MOQ) and lead times can vary significantly among suppliers, often depending on the type of vending machines and customization involved. Generally, MOQs can range from a single unit to several dozen machines. Lead times may also differ based on production schedules and shipping logistics, typically ranging from a few weeks to several months. It’s advisable to discuss these parameters upfront with suppliers to align your business needs with their capabilities, especially if you have a tight launch timeline. -

What payment terms should I expect when purchasing vending machines internationally?

Payment terms can vary widely depending on the supplier and the transaction’s scale. Common payment methods include wire transfers, letters of credit, and escrow services, especially for larger orders. Some suppliers may require a deposit upfront, with the balance due upon shipment or delivery. It’s essential to negotiate favorable terms that protect your interests, especially when engaging with suppliers in different countries. Consider the currency exchange risks and transaction fees that may arise when dealing internationally. -

How can I ensure quality assurance and certifications for vending machines?

To ensure quality assurance, request documentation of certifications relevant to your market, such as ISO standards or local compliance certifications. Reputable suppliers will provide details about their manufacturing processes, quality control measures, and any applicable warranties. It’s also beneficial to conduct factory visits or request third-party inspections, especially for large orders. Regular communication with your supplier about quality expectations will help mitigate risks and ensure that the machines meet your operational standards. -

What logistics considerations should I keep in mind when importing vending machines?

Logistics play a critical role in the successful importation of vending machines. Consider factors such as shipping methods (air vs. sea), customs regulations, and import duties specific to your country. Engage with logistics providers experienced in handling machinery to ensure proper handling and timely delivery. Additionally, factor in lead times for customs clearance, which can vary by region. Proper planning and coordination with your supplier and logistics partner can prevent delays and unexpected costs.

Illustrative Image (Source: Google Search)

-

How should I handle disputes with vending machine suppliers?

Disputes with suppliers can arise from various issues, including product quality, delivery delays, or payment disagreements. To manage disputes effectively, maintain clear and open communication with your supplier throughout the process. Having a written contract that outlines terms and conditions, including dispute resolution procedures, can provide a framework for addressing issues. If a dispute escalates, consider mediation or arbitration as alternatives to litigation, as these methods can be less costly and time-consuming. -

What are the best practices for maintaining vending machines after purchase?

Regular maintenance is essential for the longevity and optimal performance of vending machines. Establish a routine inspection schedule to check for mechanical issues, product expiration, and cleanliness. Train staff on basic troubleshooting to address minor problems promptly. Partner with suppliers for ongoing support and service agreements, which can include maintenance services or access to spare parts. Additionally, monitoring sales data can help identify trends and adjust inventory effectively, ensuring that the machines remain profitable.

Strategic Sourcing Conclusion and Outlook for are vending machines a good investment

In summary, vending machines represent a unique investment opportunity for international B2B buyers across diverse markets. The ability to adapt offerings to local tastes and preferences is crucial, particularly in regions like Africa, South America, the Middle East, and Europe. By strategically sourcing machines that are reliable, energy-efficient, and tailored to the target demographic, businesses can enhance their revenue streams while minimizing operational risks.

Key Takeaways:

– Market Research: Conduct thorough market research to identify popular products and optimal locations for vending machine placements.

– Supplier Relationships: Build strong partnerships with suppliers to ensure consistent product availability and support services.

– Technological Integration: Leverage technology, such as cashless payment systems and inventory management software, to streamline operations and improve customer experience.

As the vending industry evolves, staying ahead of trends—such as health-focused options and eco-friendly machines—will be essential. International B2B buyers are encouraged to explore these avenues and harness the potential of vending machines as a sustainable investment. Now is the time to act, evaluate your options, and make informed sourcing decisions that align with your strategic goals.