Optimize Your Investment in Water Bottle Vending Machines

Guide to Water Bottle Vending Machine

- Introduction: Navigating the Global Market for water bottle vending machine

- Understanding water bottle vending machine Types and Variations

- Key Industrial Applications of water bottle vending machine

- Strategic Material Selection Guide for water bottle vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for water bottle vending machine

- Comprehensive Cost and Pricing Analysis for water bottle vending machine Sourcing

- Spotlight on Potential water bottle vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for water bottle vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the water bottle vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of water bottle vending machine

- Strategic Sourcing Conclusion and Outlook for water bottle vending machine

Introduction: Navigating the Global Market for water bottle vending machine

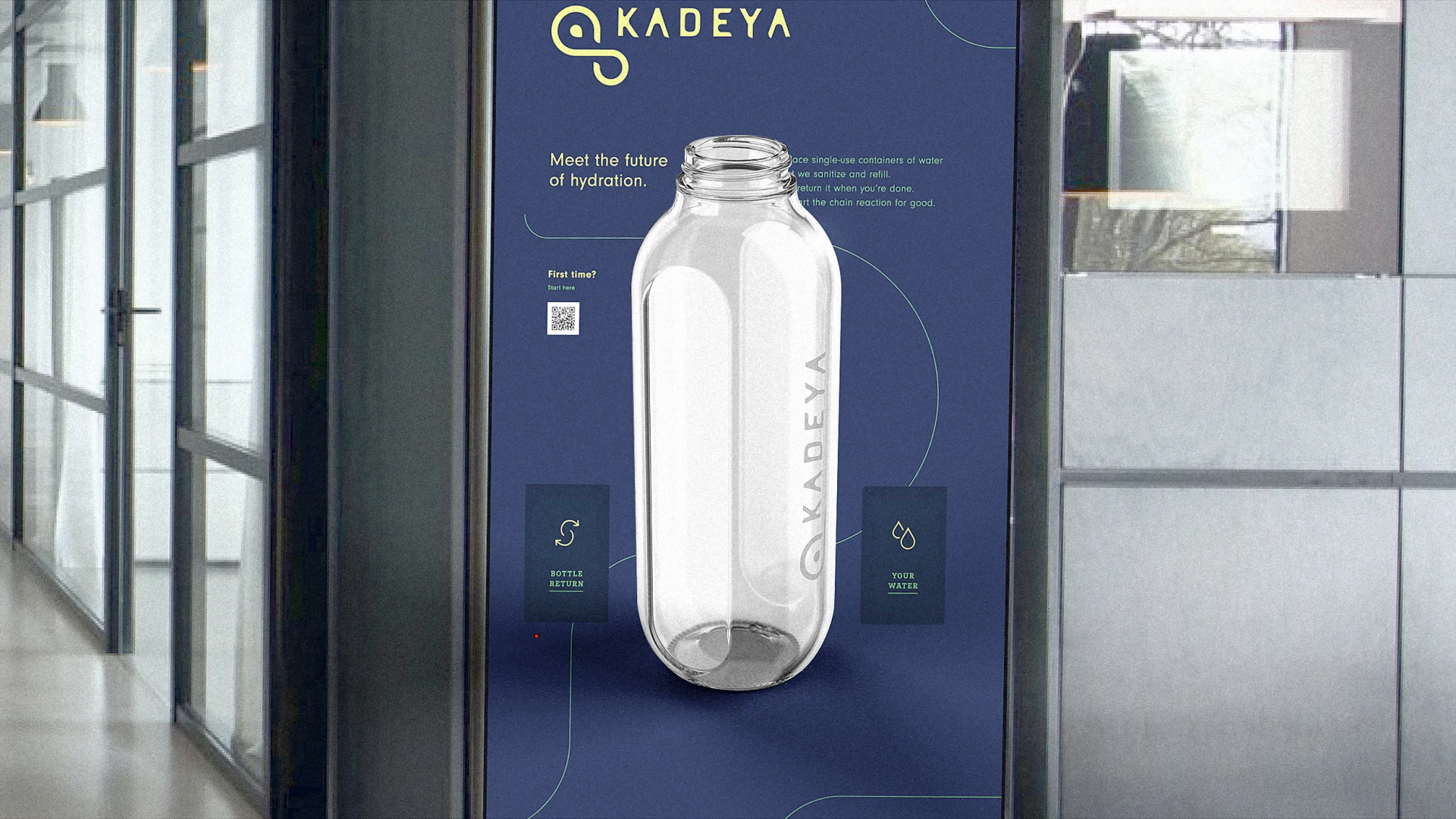

In today’s fast-paced world, the demand for convenient hydration solutions is on the rise, making water bottle vending machines a vital asset for businesses across various sectors. These machines not only cater to health-conscious consumers but also present a lucrative opportunity for international B2B buyers looking to enhance their product offerings. As urbanization continues to grow in regions such as Africa, South America, the Middle East, and Europe, investing in water bottle vending machines can significantly boost customer satisfaction and drive sales.

This comprehensive guide aims to equip B2B buyers with essential insights into the water bottle vending machine market. It covers a wide array of topics, including the different types of machines available, materials used in their construction, manufacturing and quality control processes, and sourcing reliable suppliers. Additionally, it provides a detailed cost analysis and explores current market trends, addressing frequently asked questions to facilitate informed purchasing decisions.

By navigating through this guide, buyers will gain a deeper understanding of how to optimize their vending machine investments. Whether you’re operating in Colombia, Australia, or elsewhere, this resource will empower you to make strategic sourcing choices that align with market demands and consumer preferences, ultimately positioning your business for success in the competitive landscape of vending solutions.

Understanding water bottle vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Bottled Water Vending Machine | Dispenses standard bottled water in various sizes | Offices, schools, gyms | Pros: Easy to use, widely accepted. Cons: Limited to standard sizes, higher operational costs. |

| Refillable Water Station | Allows customers to refill their own containers | Parks, events, universities | Pros: Eco-friendly, cost-effective for frequent users. Cons: Requires regular maintenance, may deter some customers. |

| Smart Water Vending Machine | Equipped with cashless payment systems and IoT features | Urban areas, tech-savvy environments | Pros: Convenient, attracts tech-oriented consumers. Cons: Higher initial investment, requires stable internet connectivity. |

| Cold and Hot Water Dispenser | Provides both chilled and hot water options | Offices, restaurants, cafes | Pros: Versatile usage, appeals to diverse customer needs. Cons: More complex machinery, higher maintenance requirements. |

| Eco-Friendly Vending Machine | Uses biodegradable materials and offers organic options | Health-focused businesses, eco-conscious venues | Pros: Attracts environmentally aware customers, aligns with sustainability goals. Cons: Potentially higher costs, limited product range. |

Standard Bottled Water Vending Machine

Standard bottled water vending machines are designed to dispense pre-packaged bottled water in various sizes, typically ranging from 500ml to 2 liters. These machines are ideal for locations such as offices, schools, and gyms, where convenience is paramount. B2B buyers should consider the reliability of the machine, ease of restocking, and the variety of bottle sizes offered. While they are easy to use and widely accepted, operational costs can be higher due to the need for regular supply and potential spoilage.

Refillable Water Station

Refillable water stations allow customers to fill their own containers, promoting sustainability by reducing plastic waste. These machines are well-suited for parks, events, and universities where high foot traffic occurs. B2B buyers must evaluate the machine’s maintenance requirements and its ability to attract eco-conscious consumers. While they are cost-effective for frequent users and environmentally friendly, they may require more upkeep and might not appeal to all customers.

Smart Water Vending Machine

Smart water vending machines are equipped with cashless payment systems and IoT features, allowing for remote monitoring and inventory management. These machines are particularly effective in urban areas and tech-savvy environments. Buyers should assess the machine’s compatibility with various payment systems and the reliability of its internet connection. Although they provide convenience and attract a modern consumer base, the initial investment can be significant, and consistent internet access is necessary for optimal performance.

Cold and Hot Water Dispenser

Cold and hot water dispensers cater to diverse customer needs by providing both chilled and hot water options. They are commonly found in offices, restaurants, and cafes, where temperature preference varies. B2B buyers need to consider the complexity of the machinery and the potential for higher maintenance requirements. The versatility of these machines is a significant advantage, but they may come with increased operational challenges.

Eco-Friendly Vending Machine

Eco-friendly vending machines focus on sustainability by utilizing biodegradable materials and offering organic water options. These machines are particularly appealing to health-focused businesses and eco-conscious venues. Buyers should evaluate the costs associated with sourcing sustainable products and the potential to attract environmentally aware customers. While they align well with sustainability goals and can differentiate a business, the higher costs and limited product range may be drawbacks.

Related Video: water vending machine features and functions introduction

Key Industrial Applications of water bottle vending machine

| Industry/Sector | Specific Application of Water Bottle Vending Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | Campus hydration stations for students and staff | Promotes health, reduces plastic waste, and provides convenience | Reliable supply of eco-friendly bottled water and machine maintenance services |

| Hospitality | Guest services in hotels and resorts | Enhances guest experience and promotes sustainability | High-quality water sources, customizable machine options, and local supplier partnerships |

| Corporate Offices | Employee wellness initiatives | Encourages hydration, improves productivity, and reduces waste | Consistent supply of bottled water, machine reliability, and service agreements |

| Events and Festivals | On-site hydration solutions for attendees | Increases accessibility to water, enhances attendee satisfaction | Flexible machine configurations, local sourcing, and quick replenishment options |

| Public Spaces | Vending solutions in parks and transportation hubs | Provides convenient access to water, encourages healthy choices | Partnerships with local water suppliers and machine durability against outdoor conditions |

Education Sector

In educational institutions, water bottle vending machines serve as hydration stations for students and staff. These machines help solve the problem of inadequate access to drinking water on campuses, thereby promoting health and wellness among the community. For international buyers, particularly in Africa and South America, sourcing machines that offer eco-friendly bottled water options is crucial, as it aligns with sustainability goals and addresses local waste management issues. Additionally, ensuring that the machines are reliable and easy to maintain is essential for long-term operation.

Hospitality Industry

In the hospitality sector, hotels and resorts utilize water bottle vending machines to enhance guest services. These machines provide guests with easy access to high-quality bottled water, which is vital for improving their overall experience. For buyers in the Middle East and Europe, sourcing machines that can be customized to reflect the hotel brand while ensuring a consistent supply of premium water is important. Furthermore, establishing partnerships with local water suppliers can help maintain quality and reduce operational costs, making it a win-win for both the business and guests.

Illustrative Image (Source: Google Search)

Corporate Offices

Corporate offices are increasingly adopting water bottle vending machines as part of their employee wellness initiatives. By providing convenient access to hydration, these machines not only encourage employees to drink more water but also contribute to a healthier workplace environment, which can lead to improved productivity. B2B buyers in regions like Europe should focus on sourcing machines that are reliable and backed by service agreements to ensure minimal downtime. Additionally, considering options for eco-friendly bottled water can further enhance corporate responsibility efforts.

Events and Festivals

At large events and festivals, water bottle vending machines offer on-site hydration solutions for attendees. This application addresses the common issue of limited access to drinking water at crowded venues, thereby enhancing attendee satisfaction and promoting healthy choices. For international buyers, it is essential to source machines that can adapt to varying event sizes and configurations. Partnering with local water suppliers for quick replenishment is also vital to meet the high demand during events, ensuring that guests remain hydrated and happy.

Public Spaces

Water bottle vending machines in public spaces, such as parks and transportation hubs, provide convenient access to hydration for the general public. This application not only encourages healthy choices but also addresses the growing concern of plastic waste by offering eco-friendly bottled water options. For buyers in Africa and South America, sourcing durable machines that can withstand outdoor conditions is critical. Establishing partnerships with local water suppliers ensures a consistent supply and supports local economies, making it a socially responsible choice.

Strategic Material Selection Guide for water bottle vending machine

When selecting materials for water bottle vending machines, it is crucial to consider factors such as durability, cost, manufacturing complexity, and compliance with international standards. Below is an analysis of four common materials used in the construction of these machines, highlighting their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Illustrative Image (Source: Google Search)

Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures and pressures. It typically has a temperature rating of up to 800°F (427°C) and can handle pressures of several thousand psi, making it suitable for various environments.

Pros & Cons:

Stainless steel is highly durable and resistant to rust and staining, which is vital for maintaining hygiene in water dispensing. However, it is more expensive than other materials and may require complex manufacturing processes, such as welding and polishing, which can increase production time.

Impact on Application:

Stainless steel is compatible with potable water and does not leach harmful substances, making it ideal for water bottle vending machines. Its robustness ensures longevity, even in high-traffic locations.

Considerations for International Buyers:

Buyers should ensure compliance with food safety standards such as FDA or EU regulations. Additionally, they should consider the availability of stainless steel grades that meet local standards, such as ASTM or DIN.

Polyethylene (PE)

Key Properties:

Polyethylene is a lightweight thermoplastic with good chemical resistance and a temperature tolerance of around -40°F to 180°F (-40°C to 82°C). It is often used in applications requiring flexibility and impact resistance.

Pros & Cons:

Polyethylene is cost-effective and easy to mold, making it suitable for high-volume production. However, it may not withstand high temperatures and can degrade under UV exposure over time, which limits its outdoor application.

Impact on Application:

PE is compatible with water and does not impart taste or odor, making it a practical choice for vending machines. However, its lower durability compared to metals may require more frequent replacements.

Considerations for International Buyers:

Buyers should check for compliance with local regulations regarding food-grade materials. Standards such as FDA for the US or EU regulations for Europe should be verified to ensure safety and quality.

Aluminum

Key Properties:

Aluminum is a lightweight metal with excellent corrosion resistance and a melting point of around 1,220°F (660°C). It is known for its good strength-to-weight ratio and is easily machined.

Pros & Cons:

Aluminum is relatively affordable and can be anodized to enhance its corrosion resistance. However, it is less durable than stainless steel and can be prone to scratching and denting, which may affect aesthetics and functionality.

Impact on Application:

Aluminum is suitable for water applications, provided that the water quality is monitored to avoid corrosion. It is often used in the frames and structural components of vending machines.

Considerations for International Buyers:

International buyers should ensure that aluminum components meet relevant standards, such as ASTM for the US or EN standards in Europe. They should also consider the environmental impact of aluminum production and recycling.

Glass

Key Properties:

Glass is a non-reactive material that can withstand high temperatures and is impermeable to gases and liquids. Its temperature tolerance can exceed 1,000°F (538°C), making it suitable for various applications.

Pros & Cons:

Glass is aesthetically pleasing and provides a premium look for vending machines. However, it is fragile and can break easily, which raises concerns about safety and durability in high-traffic areas.

Impact on Application:

Glass is ideal for displaying bottled water, as it does not interact with the contents, ensuring purity. However, its weight and fragility may limit its use in certain environments.

Considerations for International Buyers:

Buyers should consider safety regulations regarding glass usage in vending machines, especially in public spaces. Compliance with local packaging and safety standards is essential to avoid legal issues.

Summary Table

| Material | Typical Use Case for water bottle vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, dispensing units | Excellent durability and corrosion resistance | Higher cost, complex manufacturing | High |

| Polyethylene | Bottles and internal components | Cost-effective, lightweight | Limited temperature resistance, UV degradation | Low |

| Aluminum | Frames and structural elements | Lightweight, good corrosion resistance | Less durable, prone to scratching | Medium |

| Glass | Display cases for bottled water | Aesthetic appeal, non-reactive | Fragile, heavy | Medium |

This strategic material selection guide provides international B2B buyers with essential insights into the materials used in water bottle vending machines, enabling informed decision-making that aligns with operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for water bottle vending machine

Manufacturing Processes for Water Bottle Vending Machines

The production of water bottle vending machines is a multifaceted process that involves several critical stages, from material preparation to assembly and finishing. Understanding these processes is essential for B2B buyers to ensure they source high-quality machines that meet their operational needs.

1. Material Preparation

The manufacturing process begins with the careful selection and preparation of materials. The primary materials used in water bottle vending machines typically include:

- Metal Components: Steel or aluminum is used for the frame and structural parts due to their durability and strength.

- Plastic Components: High-density polyethylene (HDPE) or polycarbonate is often used for the vending compartments and bottles, as these materials are lightweight and resistant to impact.

- Electronic Components: Circuit boards, sensors, and payment systems are sourced from specialized suppliers, ensuring they comply with the latest technology standards.

During this stage, materials are inspected for quality and compliance with international standards. For instance, buyers should ensure that materials meet environmental regulations and safety standards relevant to their markets.

2. Forming

After material preparation, the next step involves forming the components of the vending machine. Key techniques used in this stage include:

- Metal Stamping: This process involves cutting and shaping metal sheets into specific forms using stamping machines. It is efficient for producing large quantities of identical components.

- Injection Molding: Used for plastic parts, this technique allows for precise shaping and is ideal for creating complex designs that are integral to the machine’s functionality.

- Laser Cutting: This method is often employed for intricate designs and ensures a high level of accuracy in component production.

The choice of forming technique impacts the durability and functionality of the vending machine, making it essential for buyers to understand these processes when evaluating suppliers.

3. Assembly

Once the components are formed, they are assembled into the final product. The assembly process typically follows these steps:

- Component Integration: All parts, including the frame, vending compartments, electronic systems, and user interface, are brought together.

- Wiring and Testing: Electrical connections are made, and initial tests are conducted to ensure functionality. This includes verifying the operation of the payment system and the dispensing mechanism.

- Quality Control Checks: During assembly, quality control checkpoints (IPQC) are established to monitor the assembly process and ensure that each component meets the required specifications.

A well-executed assembly process is crucial for the reliability of the vending machine, which directly impacts customer satisfaction.

4. Finishing

The final stage of manufacturing involves finishing processes that enhance the machine’s appearance and durability:

- Surface Treatment: This may include powder coating or painting to protect against corrosion and improve aesthetics.

- Final Assembly and Calibration: All components are calibrated to ensure proper operation, including the adjustment of dispensing mechanisms and electronic systems.

- Final Quality Control (FQC): A comprehensive inspection is conducted to ensure that the vending machine meets all specifications and functions correctly.

This stage is critical as it determines the overall quality and reliability of the vending machine.

Quality Assurance in Manufacturing

Quality assurance (QA) is a vital component of the manufacturing process for water bottle vending machines. It ensures that products meet international standards and customer expectations. Key aspects of QA include compliance with various standards and rigorous testing procedures.

International Standards

B2B buyers should be aware of the following international standards that are relevant to the manufacturing of vending machines:

- ISO 9001: This standard focuses on quality management systems and ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: For machines sold in Europe, CE marking indicates compliance with EU safety, health, and environmental protection standards.

- API Standards: The American Petroleum Institute provides standards for components used in vending machines that may dispense liquids under pressure.

Quality Control Checkpoints

Effective quality control involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): At this stage, raw materials and components are inspected upon arrival to ensure they meet quality standards.

- In-Process Quality Control (IPQC): Ongoing checks are performed during manufacturing to catch defects early in the process.

- Final Quality Control (FQC): A thorough inspection of the finished product ensures that it meets all specifications before shipment.

Common Testing Methods

To validate the quality of vending machines, manufacturers typically employ various testing methods:

- Functional Testing: Ensures that all components operate correctly under expected conditions.

- Durability Testing: Assesses the machine’s ability to withstand wear and tear over time.

- Compliance Testing: Verifies adherence to safety and quality standards.

Verifying Supplier Quality Control

For international B2B buyers, it is crucial to verify the quality control processes of potential suppliers. Here are some actionable steps:

- Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and adherence to quality standards.

- Request Quality Reports: Suppliers should provide documentation detailing their quality control procedures and results from testing phases.

- Engage Third-Party Inspectors: Hiring independent inspectors to assess quality can provide an unbiased view of the supplier’s capabilities.

Navigating Quality Control Nuances

B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe should be aware of the following nuances:

- Regulatory Compliance: Different regions have varying regulatory requirements. Buyers should ensure that suppliers comply with local laws and international standards relevant to their market.

- Cultural Considerations: Understanding cultural differences in business practices can facilitate better communication and negotiation with suppliers.

- Logistics and Supply Chain: Consider the logistics involved in sourcing machines internationally, including shipping times and customs regulations, which can impact the timely delivery of high-quality products.

By thoroughly understanding the manufacturing processes and quality assurance practices associated with water bottle vending machines, B2B buyers can make informed decisions that will ultimately enhance their operations and customer satisfaction.

Related Video: Plastic bottle manufacturing process – explained by UpSkul

Comprehensive Cost and Pricing Analysis for water bottle vending machine Sourcing

Understanding the cost structure and pricing dynamics of water bottle vending machines is crucial for international B2B buyers. This analysis covers the key cost components, price influencers, and actionable tips to enhance negotiation strategies and ensure cost-efficiency, especially for buyers from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary materials for manufacturing water bottle vending machines include high-quality stainless steel, plastic for the body, and components like cooling systems and electronic circuits. The cost of these materials can fluctuate based on market demand and availability.

-

Labor: Labor costs vary significantly across regions. In developing regions, labor may be less expensive, but ensure that the workforce is adequately skilled to maintain quality standards. In contrast, Europe and North America may have higher labor costs, which need to be factored into the overall budget.

-

Manufacturing Overhead: This encompasses costs related to facility maintenance, utilities, and indirect labor. These overheads can significantly affect the final pricing of the machines, especially in regions where energy and operational costs are high.

-

Tooling: The initial investment in tooling is essential for producing high-quality machines. This includes molds for plastic parts and machinery for assembling the units. Tooling costs can vary depending on the complexity of the machine design.

-

Quality Control (QC): Implementing a robust QC process is crucial to ensure that each machine meets safety and performance standards. This may involve additional costs for testing equipment and quality assurance personnel.

-

Logistics: Shipping costs can be a significant factor, particularly for international shipments. These costs include freight, customs duties, and insurance. The choice of shipping method (air vs. sea) will also impact the overall logistics expenses.

-

Margin: Manufacturers typically add a markup to cover their costs and achieve profit. Understanding the typical profit margins in the vending machine industry can help buyers negotiate better pricing.

Price Influencers

-

Volume/MOQ: The minimum order quantity (MOQ) can greatly influence pricing. Higher volumes often lead to lower per-unit costs, making it advantageous for buyers to consolidate orders.

-

Specifications/Customization: Customized machines with specific features (like advanced payment systems or unique branding) will typically incur higher costs. Be clear about your needs to avoid unnecessary expenses.

-

Materials: The choice of materials not only affects durability but also the price. Sustainable materials may have a premium, but they can enhance brand value.

-

Quality/Certifications: Machines that meet international quality standards or certifications (like ISO) may come at a higher price. However, these certifications can enhance marketability and reduce liability risks.

-

Supplier Factors: The reliability and reputation of suppliers can influence pricing. Established suppliers may offer better quality assurance but at a premium price.

-

Incoterms: Understanding Incoterms is vital for managing shipping and logistics costs effectively. Terms like FOB (Free on Board) or CIF (Cost, Insurance, Freight) can change the total cost of ownership significantly.

Buyer Tips

-

Negotiation: Leverage your purchasing power by negotiating on price, especially if you are ordering in bulk. Don’t hesitate to request discounts or payment terms that favor cash flow.

-

Cost-Efficiency: Conduct a thorough analysis of the total cost of ownership (TCO), which includes not just the purchase price but also installation, maintenance, and operational costs over the machine’s lifespan.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, machines sourced from Europe may be more expensive due to higher labor and material costs. In contrast, sourcing from regions with lower production costs may yield savings.

-

Market Research: Stay informed about market trends and competitor pricing to ensure you are making competitive offers. Understanding local demand can also help in negotiating better terms with suppliers.

Disclaimer

Prices provided in this analysis are indicative and can vary based on various factors, including market conditions, supplier negotiations, and specific buyer requirements. Always conduct due diligence and obtain multiple quotes to ensure competitive pricing.

Spotlight on Potential water bottle vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘water bottle vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for water bottle vending machine

Key Technical Properties of Water Bottle Vending Machines

Understanding the essential technical properties of water bottle vending machines is crucial for international B2B buyers. These specifications impact machine performance, longevity, and customer satisfaction. Below are critical specifications that should be considered:

-

Material Grade: The quality of materials used in the construction of vending machines, such as stainless steel or high-grade plastics, determines durability and resistance to corrosion. High-grade materials are essential for machines placed in outdoor environments or high-traffic areas, ensuring a longer lifespan and reduced maintenance costs.

-

Capacity and Size: This refers to the number of bottles the machine can hold and its physical dimensions. Buyers must assess their target market’s demand and space availability. A machine with a larger capacity may be beneficial in high-demand locations, while compact models are suitable for smaller venues.

-

Power Requirements: Understanding the power consumption of the vending machine is vital. Machines with energy-efficient designs not only reduce operational costs but also align with global sustainability trends, an increasingly important factor for businesses in Africa, South America, the Middle East, and Europe.

-

Temperature Control: This specification includes the machine’s ability to maintain optimal water temperatures. Effective temperature control ensures product quality and customer satisfaction, especially in regions with varying climates. Buyers should evaluate machines with advanced cooling technology to enhance performance.

-

User Interface: The design and functionality of the user interface, including touchscreens or buttons, play a significant role in user experience. A well-designed interface can facilitate easier transactions, reducing the likelihood of user errors and improving overall sales.

-

Payment Systems: Compatibility with various payment methods, including credit cards, mobile payments, and cash, is essential. Machines that support multiple payment options can cater to a broader customer base, enhancing sales potential.

Common Trade Terminology in the Vending Machine Industry

Familiarity with industry jargon is vital for effective communication and negotiation in the vending machine market. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts and equipment that may be marketed by another manufacturer. For buyers, sourcing from OEMs can ensure quality and reliability in the components used in vending machines.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is crucial for buyers to manage inventory costs effectively and to ensure they can meet demand without overstocking.

-

RFQ (Request for Quotation): This is a standard business process where a buyer requests a quote from suppliers for specific products or services. Utilizing RFQs allows buyers to compare prices and terms from different vendors, ensuring they secure the best deal.

-

Incoterms (International Commercial Terms): These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities associated with the delivery of vending machines.

-

Lead Time: This term describes the amount of time it takes from placing an order to receiving the product. Understanding lead times helps buyers plan their inventory and ensure machines are stocked and operational when needed.

-

Warranty and Service Agreement: This refers to the terms under which a manufacturer or supplier guarantees the machine’s performance and provides repair services. A clear warranty and service agreement can protect buyers from potential future costs and operational disruptions.

By grasping these technical properties and industry terms, international B2B buyers can make informed decisions, ensuring they select the right water bottle vending machines for their markets while optimizing their supply chain management.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the water bottle vending machine Sector

Market Overview & Key Trends

The water bottle vending machine sector is experiencing significant growth driven by several global trends. Increasing urbanization, a rising health consciousness, and a preference for convenient hydration solutions are shaping market dynamics. In regions such as Africa and South America, where access to clean drinking water can be inconsistent, vending machines offer an accessible solution. Emerging technologies like IoT-enabled machines are enhancing operational efficiency, enabling remote monitoring, and facilitating dynamic pricing strategies that respond to real-time demand.

B2B buyers should be aware of the ongoing shift towards contactless payment systems and digital interfaces that improve user experiences. Moreover, sustainability is becoming a critical factor influencing purchasing decisions. Machines that offer refillable options or use eco-friendly materials are gaining traction among environmentally conscious consumers, particularly in Europe and the Middle East. Buyers should also consider the integration of smart technology that tracks inventory levels and provides data analytics, which can lead to more informed stocking decisions and reduced operational costs.

As competition intensifies, it is essential for international B2B buyers to seek reliable suppliers who not only provide quality machines but also demonstrate a strong understanding of local market needs. Building partnerships with manufacturers that prioritize innovation and sustainability will be crucial for long-term success in this evolving landscape.

Sustainability & Ethical Sourcing in B2B

Sustainability in the water bottle vending machine sector is increasingly important as consumers demand environmentally responsible products. The production and disposal of traditional plastic bottles have significant environmental impacts, prompting a shift toward sustainable alternatives. B2B buyers should prioritize suppliers that utilize recycled materials or biodegradable options for their vending machines. This not only aligns with consumer preferences but also mitigates potential regulatory risks associated with plastic waste.

Ethical sourcing is essential in establishing a reputable brand. Suppliers who adhere to strict labor and environmental standards contribute to a more sustainable supply chain. Certifications such as ISO 14001 for environmental management and Fair Trade can enhance a company’s credibility and appeal to socially conscious consumers. Additionally, implementing a transparent supply chain allows buyers to trace the origin of materials used in vending machines, ensuring compliance with ethical standards.

Investing in machines that promote refillable water options can further reduce environmental footprints and resonate well with eco-conscious markets. As sustainability becomes a pivotal factor in purchasing decisions, B2B buyers must integrate these principles into their sourcing strategies to remain competitive and responsible.

Brief Evolution/History

The concept of vending machines dates back to ancient Greece, where devices dispensed holy water in temples. However, the modern vending machine industry began in the early 20th century, with the introduction of machines that sold snacks and beverages. The emergence of bottled water vending machines is relatively recent, driven by the growing demand for convenient access to clean drinking water. Over the past two decades, innovations in technology, such as cashless payment systems and smart inventory management, have transformed the sector, making it a viable option for B2B buyers seeking to capitalize on consumer trends towards health and convenience. Today, the focus on sustainability and ethical sourcing continues to shape the evolution of water bottle vending machines, aligning the industry with broader environmental goals.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of water bottle vending machine

-

What should I consider when vetting suppliers for water bottle vending machines?

When vetting suppliers, evaluate their reputation, experience, and customer reviews. Look for certifications that ensure quality and compliance with international standards, such as ISO or CE certifications. Request references from other clients, particularly those in your region, to gauge reliability. Additionally, assess their capacity to meet your specific requirements, including customization options and after-sales support. -

Can I customize the water bottle vending machines according to my brand?

Yes, many suppliers offer customization options, allowing you to incorporate your branding elements such as logos, color schemes, and specific functionalities. Discuss your requirements early in the negotiation process to ensure the supplier can accommodate your needs. Customization can enhance brand visibility and customer engagement, making it a worthwhile investment. -

What are the typical minimum order quantities (MOQ) and lead times for water bottle vending machines?

MOQs can vary significantly based on the supplier and the complexity of the machines. Generally, expect MOQs ranging from 5 to 50 units. Lead times also vary, typically ranging from 4 to 12 weeks, depending on the level of customization and the supplier’s production capacity. Always confirm these details upfront to align your purchasing strategy with your operational timelines. -

What payment terms should I expect when sourcing vending machines internationally?

Payment terms can differ widely among suppliers. Common practices include a deposit (usually 30-50%) upfront, with the balance due upon shipment or delivery. For larger orders, consider negotiating terms that may include payment by letter of credit or installment payments. Ensure to clarify these terms in your contract to avoid misunderstandings. -

How can I ensure quality assurance (QA) and necessary certifications for the machines?

Request detailed documentation of the quality assurance processes from your supplier, including testing protocols and certifications. Suppliers should be able to provide evidence of compliance with local and international standards, such as CE or UL certifications. Consider conducting an on-site inspection or hiring a third-party inspection service to verify quality before shipment. -

What logistics considerations should I keep in mind for shipping vending machines?

Logistics are crucial in international trade. Assess the supplier’s ability to handle shipping arrangements, including freight costs, insurance, and delivery timelines. Ensure that the machines are packaged securely to withstand transit. It’s advisable to use reliable freight forwarders familiar with customs regulations in your region to prevent delays and additional costs. -

How can I handle disputes or issues with suppliers effectively?

Establish clear communication channels and document all agreements in writing to minimize disputes. If issues arise, engage in open discussions to seek amicable solutions. If necessary, refer to dispute resolution mechanisms specified in your contract, such as arbitration or mediation. Building a strong relationship with your supplier can also help mitigate conflicts in the long run. -

What trends should I be aware of in the water bottle vending machine market?

Stay informed about trends such as the shift towards eco-friendly materials and smart technology integration, like cashless payment systems and remote monitoring capabilities. Consumers are increasingly seeking sustainable options, so consider machines that offer refillable bottle features or use biodegradable materials. Keeping abreast of these trends can help you remain competitive and responsive to market demands.

Strategic Sourcing Conclusion and Outlook for water bottle vending machine

Strategic sourcing is a pivotal component in the success of water bottle vending machines, particularly for international B2B buyers. By focusing on quality products that resonate with local consumer preferences, businesses can enhance their profit margins and operational efficiency. Establishing strong relationships with reliable suppliers ensures a steady flow of high-demand items, while an understanding of regional market dynamics allows for informed decision-making.

As the market evolves towards sustainability, aligning product offerings with eco-friendly trends can set businesses apart in competitive landscapes. Buyers must remain agile, adapting their strategies to incorporate innovative solutions that meet the growing demand for environmentally conscious products.

Looking ahead, the opportunities in the water bottle vending sector are vast. International buyers, especially from regions such as Africa, South America, the Middle East, and Europe, should actively seek partnerships that align with their business goals. By investing in strategic sourcing and maintaining a customer-centric approach, companies can not only thrive in the vending industry but also contribute positively to the global movement towards sustainable consumption. Embrace these insights and take decisive action to position your business for future success in this dynamic market.